With the rapid evolution of aerospace industry toward high-performance, lightweight, and long-life solutions, Aerospace components like structural frames, turbine blades, and engines have transitioned from conventional precision standards to micron-level composite machining.Machine manufacturer must simultaneously deliver ultra-high rigidity, multi-axis linkage accuracy, and complex process integration capabilities.

Taikan’s CNC intelligent machining solutions are tailored to meet the demands of the aerospace industry. With high precision, high efficiency, high integration, and digitalization, We ensure exceptional quality of critical components under high temperature, high speed, and harsh conditions. Supporting lightweight design and cost optimization, Taikan is driving the aerospace manufacturing industry toward a smarter and more efficient future.

Taikan CNC Machining Solutions for the aerospace Industry

Scene 1: Impeller, blade disk, casing processing

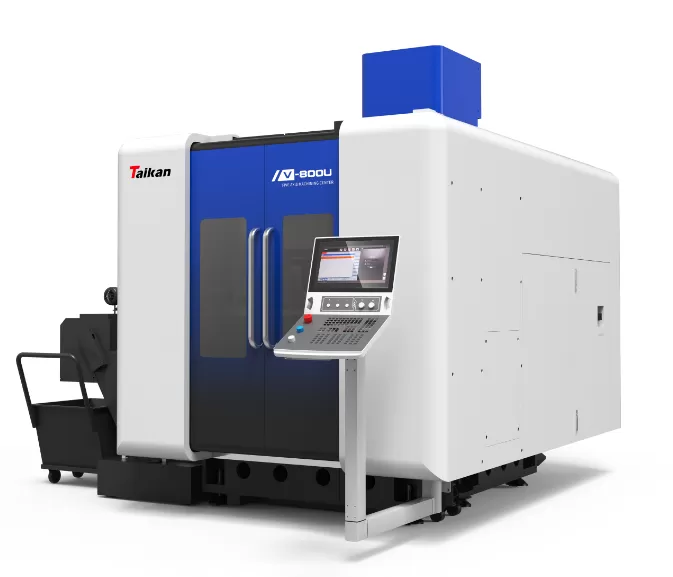

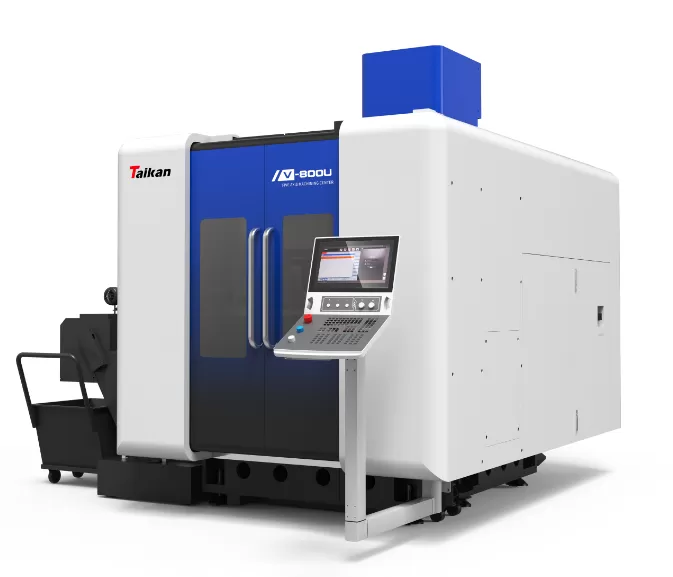

Recommended Model:

Main Product Parameters:

Max. Spindle speed: 16000r/min

Tool Magazine Capacity: 40T

X/Y/Z Axis Travel (mm): 850/900/580

Spindle power: 30 kW

Processing Features:

High-precision DD direct-drive rotary table.

Advanced A-axis dual torque motor dual-drive technology, paired with Y-axis dual-screw dual-drive structural technology.

Equipped with Siemens 5-axis CNC system, digital assistance for efficient production.

Scene 2: Aviation parts, motor frames processing

Recommended Model:

Main Product Parameters:

Spindle speed range r/min: 3.15〜400

Max. swing diameter: 1400

Max. turning diameter: 1250

Turret type: 8-bit ATC

Processing Features:

Bed-type, thermally symmetric structure with major parts made from high-strength cast iron to ensure stability and rigidity.

Reinforced with a large cross-section beam – stronger resistance to bending and torsion, ensuring ultimate cutting stability.

High torque spindle motor, equipped with a gear reducer to provide wide spindle speed range and support heavy-duty cutting.

Scene 3: Screw rotor, landing gear, impeller processing

Recommended Model:

Main Product Parameters:

X/Y/Z axis travel: 1000×1150×1000 mm

Motorized spindle speed: standard 12000 rpm

Max. tool diameter: 150mm

Spindle power: 52 kW/73kW

Processing Features:

5-axis universal milling head and high-load turning-milling rotary table enable synchronized high-torque cutting with full closed-loop control, precision feed, and vertical/horizontal conversion.

Renishaw NC4 laser tool setter supports online measurement for tools up to Ø150mm.

Monolithic marble bed/column structure ensures high rigidity for combined turning-milling operations.

Scene 4: Crankshaft and screw processing

Recommended Model:

Main Product Parameters:

X/Y/Z axis travel: 650/400/2030 mm

Rapid traverse speed: 40/40/50m/min

Tool magazine capacity: 36T

X/Y/Z Feed force: 12/9/12KN

Processing Features:

Optimized mechanical line casting analysis and design

Z1/Z3 axes hollow-cooled ball screw drive, B-axis Direct Drive transmission

Tempering with natural aging treatment for internal stress relief. Natural frequency vibration of the structure eliminates material processing stress.

Why Choose Taikan

9 CNC machine tool series with customizable configurations to meet most machining needs.

20 years of industry experience and 700+ core patents, leading the industry.

ISO-certified, high-precision machines, trusted by global customers.

Sales and service network covering 50+ countries and regions, ensuring rapid response.

After-sales service: Professional support and maintenance training.

High-quality, long-lasting genuine parts, with strict quality control from procurement to manufacturing.

Standardized training for distributors, ensuring top-quality service.

Welcome to contact us!

Vertical Machining Center Drilling and Milling Machining Center Profile Machining Center Horizontal Machining Center 5-Axis Machining Center Gantry Machining Center CNC Multi-Head High-Speed Machining Center CNC Lathe CNC Slitting Automatic LatheS series Standard Edition with 3-Axis Linear Guide Rails H Series Advanced Edition with 3-Axis Linear Guide Rails M Series Excellent Rigidity T-V Series Light Cutting W Series Hub Machining L Series Two Rails and One Hard Rail T Series 3-Axis Hard Rail DT Series High Precision Vertical Machining CenterB Series Drilling & Milling Machining Center S Series Drilling & Milling Machining Center SE Series Drilling & Milling Machining CenterT Series Moving Column Type & BT30 (Tilt-Disc Tool Magazine) V Series Moving Column Type & BT40 (Tilt-Disc Tool Magazine)T-H11 Horizontal Machining Center DH-63 Horizontal Machining Center DH-100S Horizontal Machining CenterG-V Series 3-Axis Linear Guides G-VU Series 5-Axis Gantry Machining Center G-BU Series Bridge 5-Axis Gantry Machining CenterSingle-Head High-Speed Engraving Machining Center Multi-Channel High-Speed Machining Center Multi-Head High-Speed Engraving Machining Center Multi-Head Vertical Machining Center

Vertical Machining Center Drilling and Milling Machining Center Profile Machining Center Horizontal Machining Center 5-Axis Machining Center Gantry Machining Center CNC Multi-Head High-Speed Machining Center CNC Lathe CNC Slitting Automatic LatheS series Standard Edition with 3-Axis Linear Guide Rails H Series Advanced Edition with 3-Axis Linear Guide Rails M Series Excellent Rigidity T-V Series Light Cutting W Series Hub Machining L Series Two Rails and One Hard Rail T Series 3-Axis Hard Rail DT Series High Precision Vertical Machining CenterB Series Drilling & Milling Machining Center S Series Drilling & Milling Machining Center SE Series Drilling & Milling Machining CenterT Series Moving Column Type & BT30 (Tilt-Disc Tool Magazine) V Series Moving Column Type & BT40 (Tilt-Disc Tool Magazine)T-H11 Horizontal Machining Center DH-63 Horizontal Machining Center DH-100S Horizontal Machining CenterG-V Series 3-Axis Linear Guides G-VU Series 5-Axis Gantry Machining Center G-BU Series Bridge 5-Axis Gantry Machining CenterSingle-Head High-Speed Engraving Machining Center Multi-Channel High-Speed Machining Center Multi-Head High-Speed Engraving Machining Center Multi-Head Vertical Machining Center

EN

EN