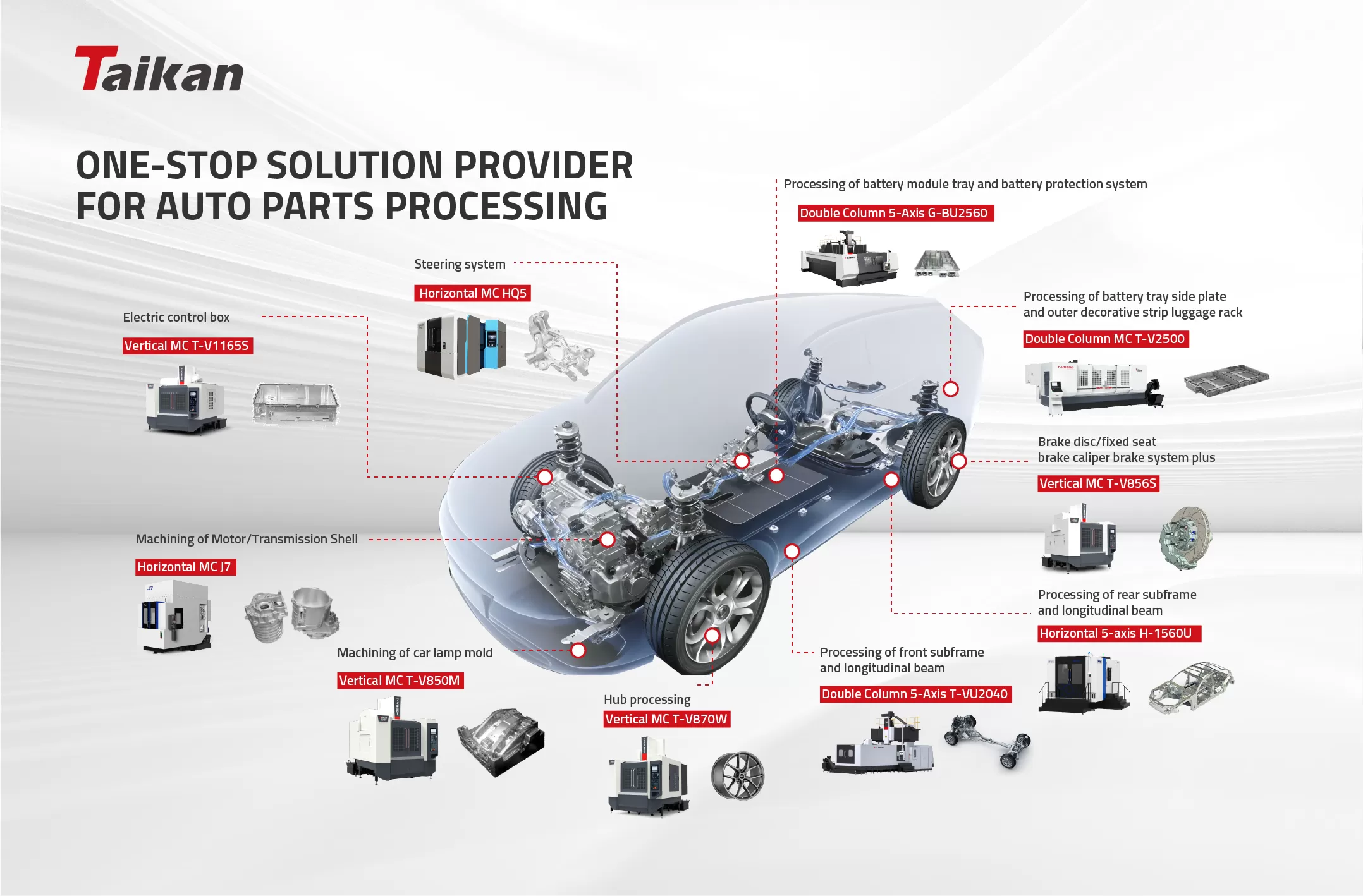

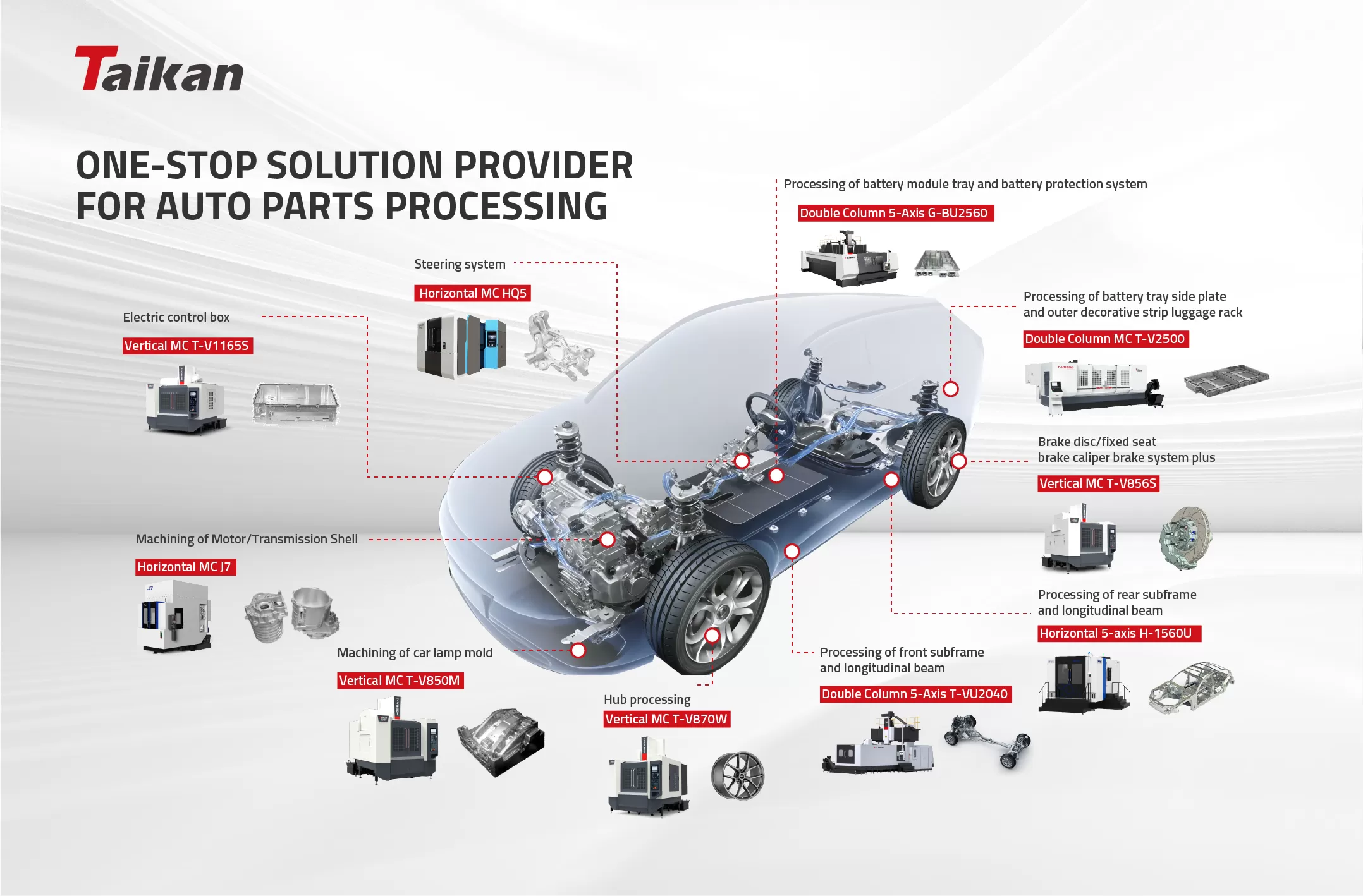

As the segments of electric vehicles, hybrid vehicles, and hydrogen fuel cell vehicles continue to grow rapidly, the processing demands for NEV components are becoming increasingly complex and diverse.

This sets higher requirements for CNC machining equipment needed for parts manufacturing. Providing high-precision, high-efficiency, and smarter integrated machining solutions for the NEV industry has become a critical focus for the CNC machining equipment sector.

Taikan provides a comprehensive set of efficient and intelligent machining solutions for the precision parts processing needs of the new energy vehicle (NEV) industry, covering the manufacturing of various core components to meet diverse customer requirements.

Taikan CNC Machining Solutions for the NEV Industry

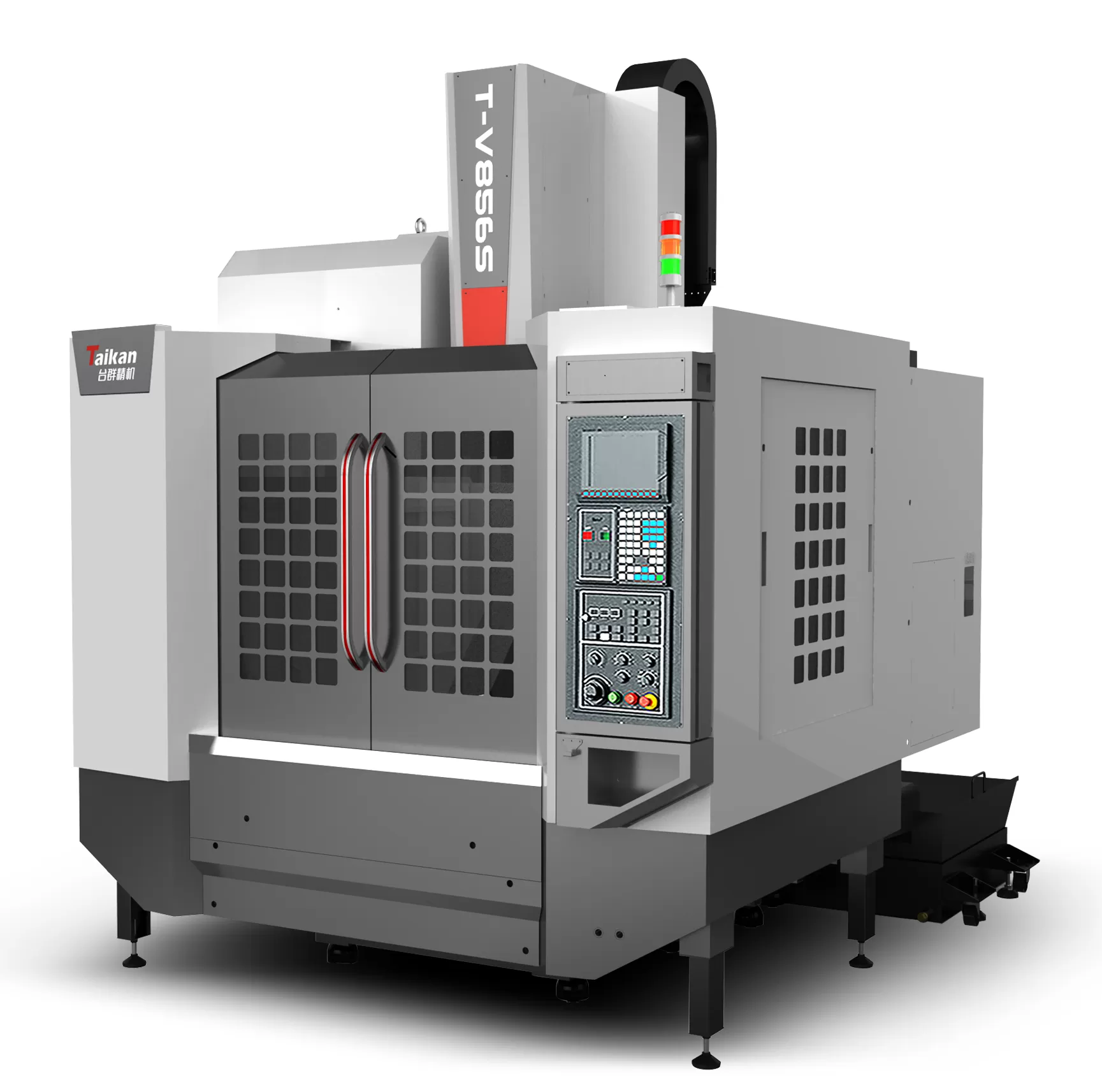

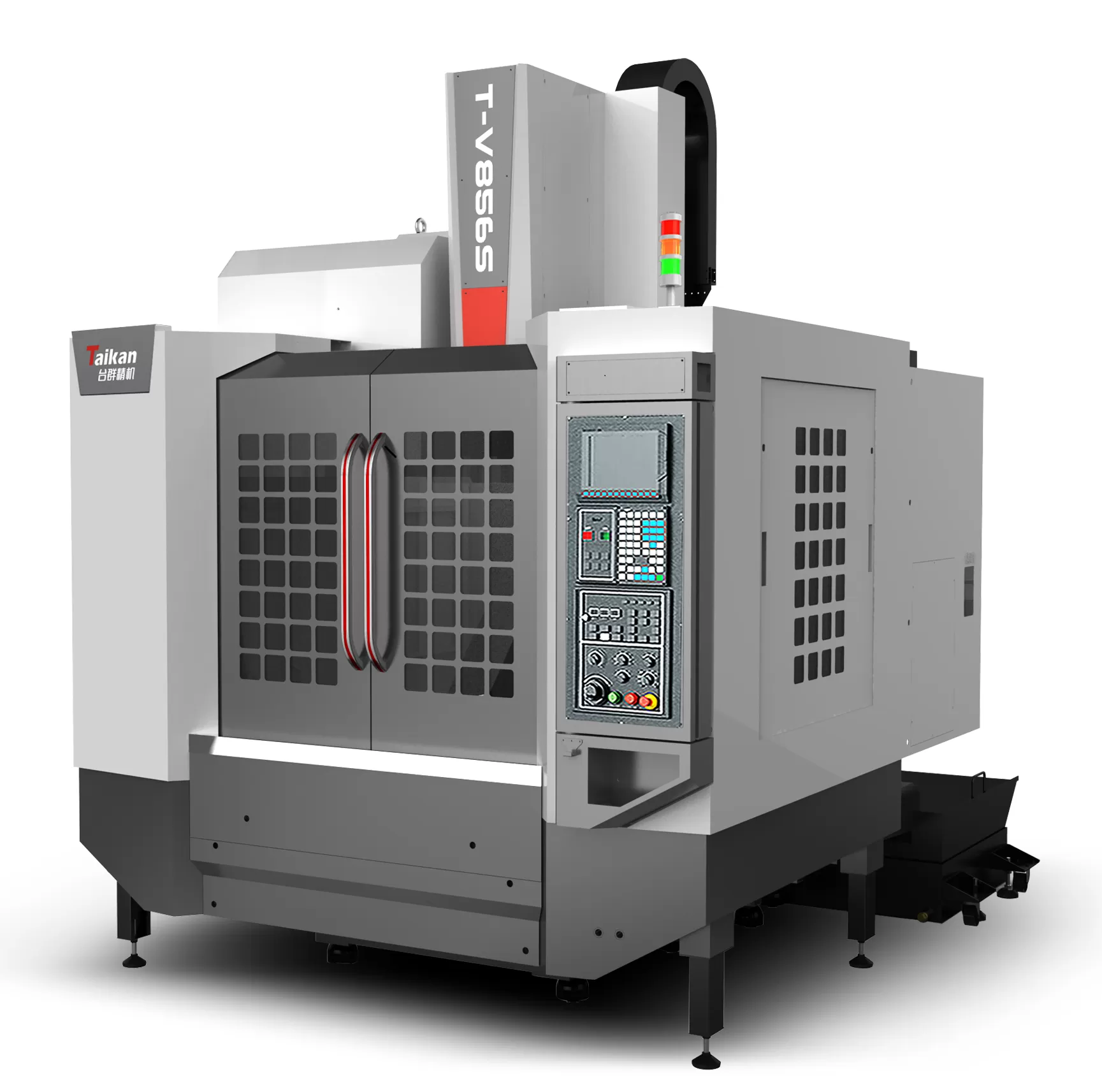

Scene 1:Brake disc/fixing seat/brake caliper brake system processing

Recommended Model:

Main Product Parameters:

X/Y/Z Axis Travel (mm): 800/550/600

X/Y/Z Axis Rapid Traverse Speed (m/min): 48/48/48

Spindle Speed (r/min): Up to 12,000 (Direct Drive)

Tool Magazine Capacity: 24T

Processing Features:

Fast processing speed and high processing efficiency. Achieves 0.005mm repeatability accuracy.

High sales volume with proven market performance, annual sales exceeding 10,000 units, available in over 50 countries and regions.

Excellent price-performance ratio among similar products.

Scene 2:Electronic control box processing

Recommended Model:

Main Product Parameters:

X/Y/Z Axis Travel (mm): 1100/650/600

X/Y/Z Axis Rapid Traverse Speed (m/min): 36/36/36

Spindle Speed (r/min): Up to 12,000 (Direct Drive)

Tool Magazine Capacity: 24T

Processing Features:

High-precision linear guides and lead screws, with improved dynamic responsiveness, high-speed cutting, and no crawling at low speeds.

High-quality resin sand molding, high-strength cast iron materials, offering high rigidity and stable accuracy.

Scene 3:Wheel Processing

Recommended Model:

Main Product Parameters:

X/Y/Z Axis Travel (mm): 850/720/650

X/Y/Z Axis Rapid Traverse Speed (m/min): 36/36/30

Spindle Speed (r/min): Up to 12,000 (Direct Drive)

Tool Magazine Capacity: 24T

Processing Features:

High-quality resin sand molding, high-strength cast iron materials, offering high rigidity and stable accuracy.

Fixed-column cross-slide table structure with a large, stable base, high-rigidity, wide-span, human-shaped vertical column, ensuring no vibration or deformation during high-speed cutting.

Specially designed for processing automobile wheels of 26 gauge and below.

Scene 4:Car Lamp Mold Processing

Recommended Model:

Main Product Parameters:

X/Y/Z Axis Travel (mm): 850/550/550

X/Y/Z Axis Rapid Traverse Speed (m/min): 36/36/30

Spindle Speed (r/min): Up to 8,000 (Belt Drive)

Tool Magazine Capacity: 24T

Processing Features:

The Z-axis features 6 slides with strong load-bearing capacity.

The 8,000-rpm belt spindle has high cutting rigidity, especially suitable for high-speed cutting of solid materials such as mold steel, offering greater efficiency advantages.

Scene 5:Battery tray side panels, exterior trim, luggage rack processing

Recommended Model:

Main Product Parameters:

X/Y/Z Axis Travel (mm): 2500/550/550

X/Y/Z Axis Rapid Traverse Speed (m/min): 50/28/28

Spindle Speed (r/min): Up to 12,000

Tool Magazine Capacity: 24T

Processing Features:

The X-axis strip transmission has fast speed, large travel, and high processing efficiency.

Particularly suitable for processing long workpieces.

Scene 6:Front subframe and longitudinal beam processing

Recommended Model:

Main Product Parameters:

X/Y/Z Axis Travel (mm): 4200/2700/1000

X/Y/Z Axis Rapid Traverse Speed (m/min): 10/15/15

Spindle Speed (r/min): Up to 18,000

Optional Tool Magazine: 24T

Processing Features:

The spindle unit adopts the Mepro T70.5 A/C double-swing milling head, which can achieve five-axis linkage processing.

Provides higher efficiency advantages in processing large, complex workpieces and curved cavity bodies.

Scene 7:Battery module tray, battery protection system processing

Recommended Model:

Main Product Parameters:

X/Y/Z Axis Travel (mm): 6200/2700/1000

X/Y/Z Axis Rapid Traverse Speed (m/min): 24/24/24

Spindle Speed (r/min): Up to 12,500

Optional Tool Magazine: 24T

Processing Features:

Five-axis linkage processing, efficiently handling medium and large complex parts and cavities.

Modular design allows for serialization and customization based on market demand.

Why Choose Taikan

9 CNC machine tool series with customizable configurations to meet most machining needs.

20 years of industry experience and 700+ core patents, leading the industry.

ISO-certified, high-precision machines, trusted by global customers.

Sales and service network covering 50+ countries and regions, ensuring rapid response.

After-sales service: Professional support and maintenance training.

High-quality, long-lasting genuine parts, with strict quality control from procurement to manufacturing.

Standardized training for distributors, ensuring top-quality service.

Welcome to contact us!

Vertical Machining Center Drilling and Milling Machining Center Profile Machining Center Horizontal Machining Center 5-Axis Machining Center Gantry Machining Center CNC Multi-Head High-Speed Machining Center CNC Lathe CNC Slitting Automatic LatheS series Standard Edition with 3-Axis Linear Guide Rails H Series Advanced Edition with 3-Axis Linear Guide Rails M Series Excellent Rigidity T-V Series Light Cutting W Series Hub Machining L Series Two Rails and One Hard Rail T Series 3-Axis Hard Rail DT Series High Precision Vertical Machining CenterB Series Drilling & Milling Machining Center S Series Drilling & Milling Machining Center SE Series Drilling & Milling Machining CenterT Series Moving Column Type & BT30 (Tilt-Disc Tool Magazine) V Series Moving Column Type & BT40 (Tilt-Disc Tool Magazine)T-H11 Horizontal Machining Center DH-63 Horizontal Machining Center DH-100S Horizontal Machining CenterG-V Series 3-Axis Linear Guides G-VU Series 5-Axis Gantry Machining Center G-BU Series Bridge 5-Axis Gantry Machining CenterSingle-Head High-Speed Engraving Machining Center Multi-Channel High-Speed Machining Center Multi-Head High-Speed Engraving Machining Center Multi-Head Vertical Machining Center

Vertical Machining Center Drilling and Milling Machining Center Profile Machining Center Horizontal Machining Center 5-Axis Machining Center Gantry Machining Center CNC Multi-Head High-Speed Machining Center CNC Lathe CNC Slitting Automatic LatheS series Standard Edition with 3-Axis Linear Guide Rails H Series Advanced Edition with 3-Axis Linear Guide Rails M Series Excellent Rigidity T-V Series Light Cutting W Series Hub Machining L Series Two Rails and One Hard Rail T Series 3-Axis Hard Rail DT Series High Precision Vertical Machining CenterB Series Drilling & Milling Machining Center S Series Drilling & Milling Machining Center SE Series Drilling & Milling Machining CenterT Series Moving Column Type & BT30 (Tilt-Disc Tool Magazine) V Series Moving Column Type & BT40 (Tilt-Disc Tool Magazine)T-H11 Horizontal Machining Center DH-63 Horizontal Machining Center DH-100S Horizontal Machining CenterG-V Series 3-Axis Linear Guides G-VU Series 5-Axis Gantry Machining Center G-BU Series Bridge 5-Axis Gantry Machining CenterSingle-Head High-Speed Engraving Machining Center Multi-Channel High-Speed Machining Center Multi-Head High-Speed Engraving Machining Center Multi-Head Vertical Machining Center

EN

EN