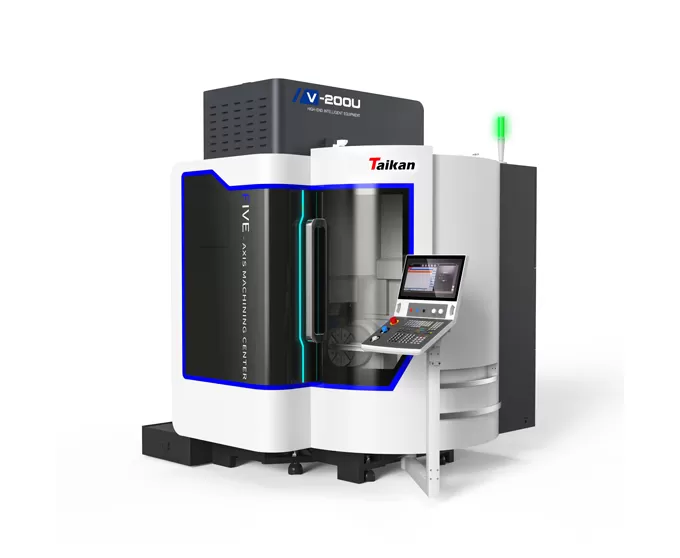

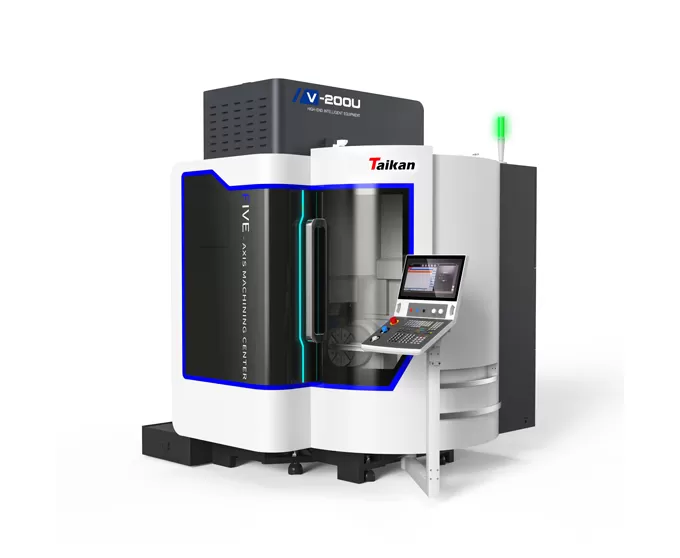

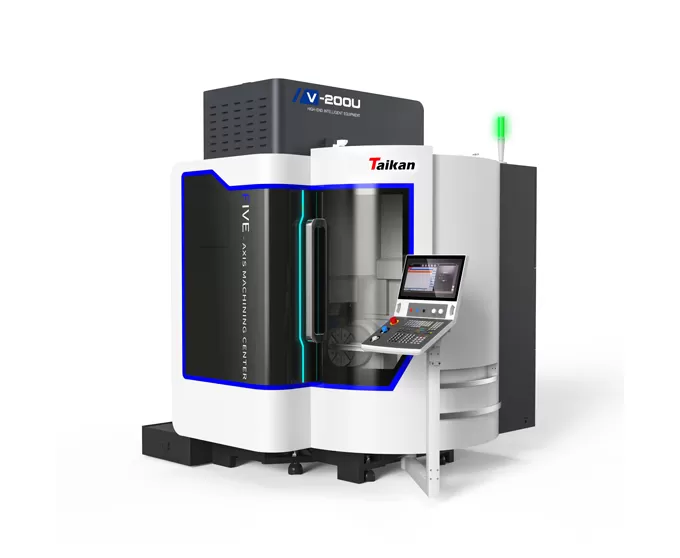

High-Rigidity Structure

High rigidity gantry-type O-shaped structure, high-quality gray cast iron material: Provides strong rigidity and stability, reducing deformation and improving accuracy.

Step-type arrangement of the beam's guide rails, short distance from the spindle to the beam: Enhances rigidity and improves machining accuracy.

Single-arm rotary table, minimized distance from the X-axis drive point to the machining point: Reduces vibration, improving precision and efficiency.

High-Precision Direct-Drive Rotary Table

High-torque frameless direct-drive motors: Provide high rigidity and precision, directly driving the B/C axes, reducing mechanical losses.

Compact structure, motor rotor integrated with the rotary mechanism: Improves stability and accuracy.

Motor stator cooled by coolant: Ensures thermal stability, reducing precision errors caused by temperature changes.

Maximum speed of B/C axes: 50r/min: Meets the demands of complex machining and improves efficiency.

High-Speed Motorized Spindle

HSK E40 high-speed motorized spindle

Maximum speed up to 30,000 rpm.

30-Tool Umbrella Magazine

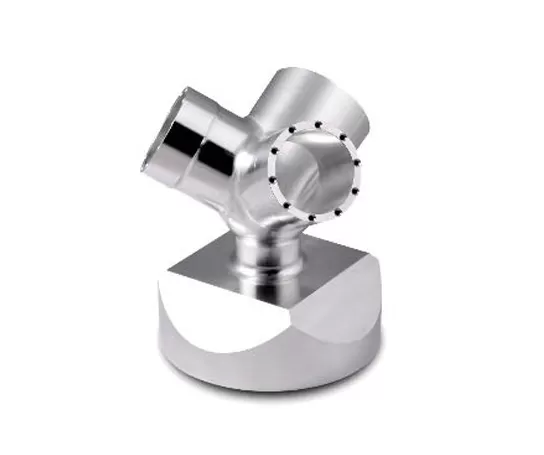

Widely used in the processing of impellers, automotive parts, precision molds, medical devices, and other complex components.

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

Workpiece Example 5

Workpiece Example 6

Workpiece Example 7

Item | Unit | V-200U | |

Travel | Travel X/Y/Z | mm | 500/280/300 |

B axis rotation range | ° | +30°~ -120° | |

C axis rotation range | ° | 360° | |

Distance from spindle nose to worktable surface | mm | 100-400 | |

Table | Table size | mm | Φ260 |

Max. load | kg | 30 | |

T-slot (number of slots - slot width * spacing) | mm | 8-14*45°(Evenly distributed) | |

Speed | X/Y/Z axis rapid traverse speed | mm/min | 24000 |

B/C axis rapid traverse rotation speed | r/min | 50/50 | |

Accuracy | X/Y/Z axis positioning accuracy | mm | 0.006/0.006/0.006 |

X/Y/Z axis repeatability accuracy | mm | 0.004/0.004/0.004 | |

B/C axis positioning accuracy | sec | 8/8 | |

B/C axis repeatability accuracy | sec | 5/5 | |

Spindle | Spindle motor power (S1/S6) | kW | 11/19 |

Spindle motor torque (S1/S6) | Nm | 5/8.7 | |

Spindle speed | r/min | 0~30000 | |

Tool holder specifications | / | HSK E40 | |

Tool magazine | Tool magazine structure | / | Umbrella tool magazine |

Tool magazine capacity | T | 30 | |

Max. tool weight | kg | 1.2 | |

Max. tool length | mm | 150 | |

Max. diameter (full /adjacent empty) | mm | φ40/φ60 | |

Others | CNC system | / | Siemens SINUMERIK ONE |

Air source pressure requirement | MPa | 0.6~0.8 | |

Total electrical capacity | kW | 32 | |

Machine size(length*width*height) | mm | 3200*4000*2700 | |

Main machine weight (approx.) | KG | 5500 | |

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

SINUMERIK ONE

Apr 11 2025

Apr 01 2025