Advanced Edition with Three Linear

High speed and high precision-A testament to exquisite craftsmanship

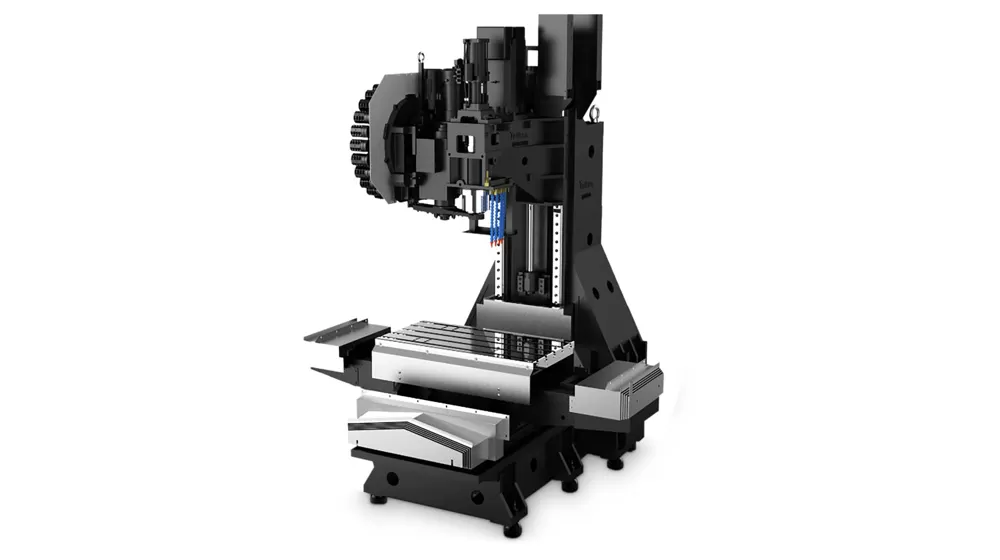

Machine Structure

The machine features a fixed column structure with a cross-type sliding table. The body is built with an extra-large stable base and a high-rigidity, wide-span A-shaped column, ensuring vibration-free and deformation-free high-speed cutting.

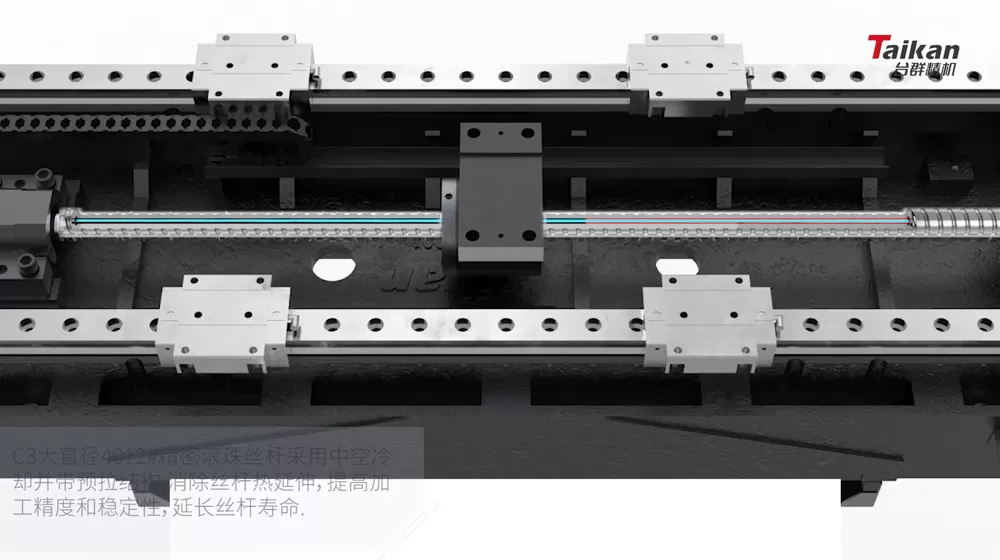

Hollow Ball Screws

Hollow ball screws with pre-tensioned structure eliminate thermal expansion, enhancing the machine's precision. The ball screw bearings are self-lubricating, extending their lifespan.

Spindle

The machine features a high-speed spindle unit from Taikan, equipped with a BT40-12000 rpm direct connection head. The spindle front uses a labyrinth design with an air curtain protection, preventing cutting fluids from entering the spindle bearings.

Tool Magazine

The machine is equipped with a 24-pocket arm-type tool magazine from Taikan, known for its reliable quality and stable performance.

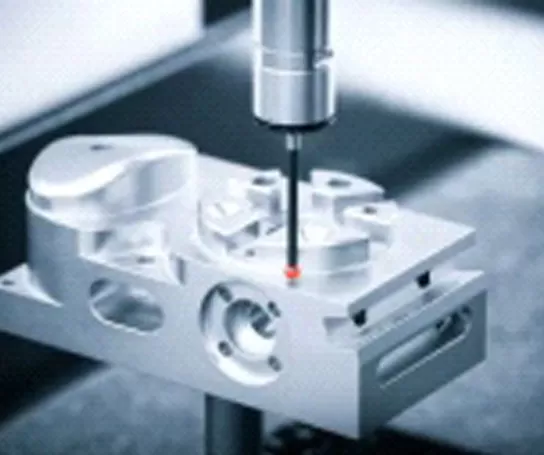

The machine tool is suitable for the multi-variety, small-batch processing of complex parts such as medium and small-sized box-shaped components, plates, disks, valves, housings, and molds. It is widely used in industries such as precision parts, 5G products, hardware, automotive parts, and medical devices.

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

Item | Unit | T-V856H | Remarks | ||

Travel | Table travel (X axis) | mm | 800 | ||

Saddle travel (Y axis) | mm | 550 | |||

Headstock travel (Z axis) | mm | 600 | |||

Distance from spindle nose to worktable surface | mm | 125~725 | |||

Distance from spindle center to column guide surface | mm | 590 | |||

Worktable | Table size | mm | 1000*500 | ||

Max. load (even load-bearing) | kg | 450 | |||

T-slot (number of slots - slot width * spacing) | mm | 5-18*100 | |||

Spindle | Motor power (rated/short time) | kW | 11/15 | ||

Motor torque (rated/short time) | N.m | 52.5/118 | |||

Speed range | r/min | 50~12000 (Directly coupled) | |||

Spindle diameter | mm | φ150 | |||

Spindle taper | / | BT40 | |||

Rivet specifications | / | P40T-I(MAS403) | |||

Speed | Cutting feed speed range | mm/min | 1-10000 | ||

X/Y/Z axis rapid traverse speed | m/min | 30/30/30 | |||

Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.008 | GB/T18400.4(Full travel) | |

Repeatability (X/Y/Z) | mm | 0.005 | |||

Tool magazine | Tool capacity | pcs | 24 | ||

Max. tool weight | kg | 7 | |||

Max. tool length | mm | 250 | |||

Max. tool diameter (full /adjacent empty) | mm | Φ75/Φ150 | |||

Others | CNC system | / | Mitsubishi M80VB | ||

Air source | Flow | L/min | ≥280(ANR) | ||

Air pressure | MPa | 0.6~0.8 | |||

Equipment capacity | KVA | 25 | |||

Coolant tank capacity | L | 300 | |||

Machine size | mm | 2240*3121*3026 | Corresponding to X*Y*Z axis | ||

Weight (approx.) | Kg | 4600 | |||

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Mitsubishi

FANUC

Siemens

Taikan

Apr 11 2025

Apr 01 2025