Cast Iron Bed and Beam

The machine is constructed with a cast iron bed and beam, providing high rigidity and stable precision over time.

Mitsubishi M80B CNC System

Equipped with the high-performance and reliable Mitsubishi M80B control system, ensuring superior control and stability.

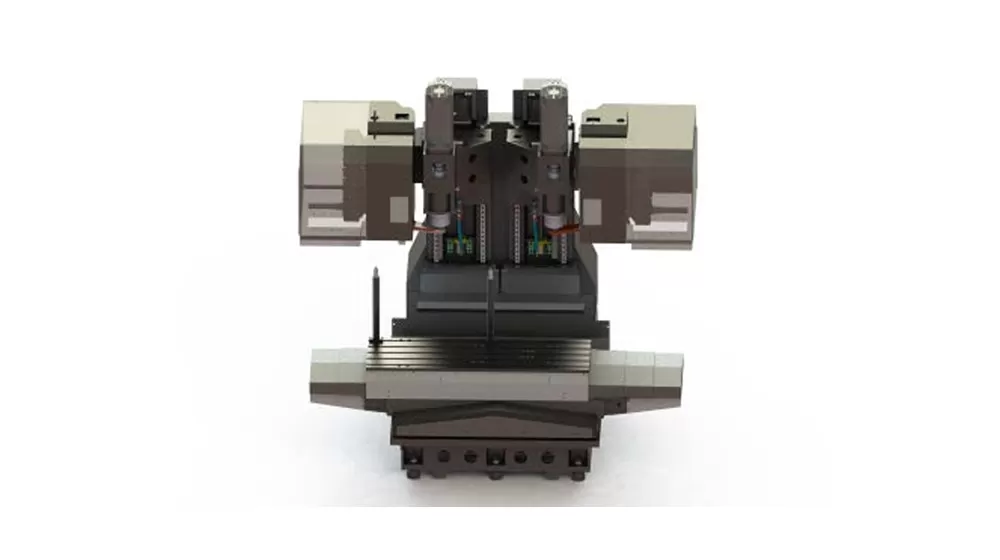

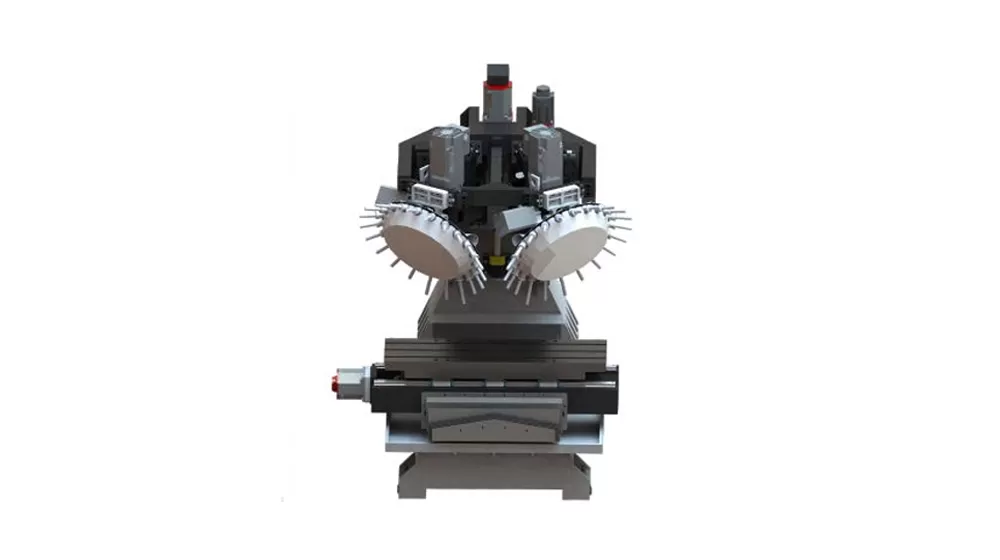

Dual 24-Tool Arm-Type Tool Magazine

Features dual 24-tool arm-type tool magazines, significantly improving machining efficiency.

Generous XYZ1/Z2 Travel

XYZ1/Z2 axis travel of 600500600/600mm allows for the machining of large-sized parts.

The T-6050-2 is ideal for the mass production of box-type products, hardware components, and new energy box-type products.

It is also suitable for the mass production of 5G box-type products, valve bodies, and disk-shaped components.

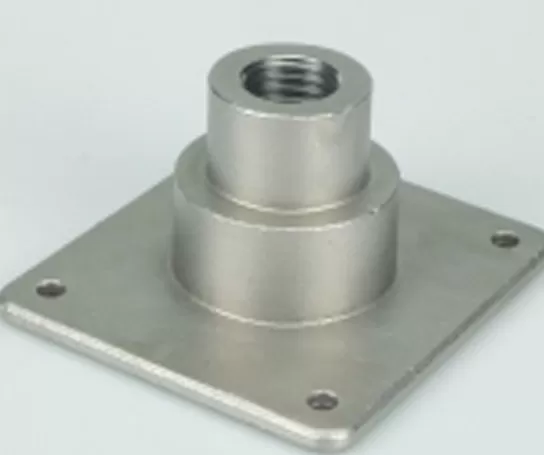

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

name | project | Parameters |

workbench | Table size (mm) | 1400*500 |

Distance from table to spindle nose (mm) | 180~780 | |

Maximum load-bearing weight (Kg) | ||

journey | X-direction travel (mm) | 600 |

Travel in Y direction (mm) | 500 | |

Ztravel (mm) | 600 | |

Spindle | Spindle power (Kw) | 7.5/11 |

Spindle maximum speed (rpm) | 12000 | |

Spindle diameter (mm) | φ150 | |

Spindle tool change method | Pneumatic tool changer | |

Shank form | BT40 | |

Feed rate | Maximum dry run feed speed (m/min) | 48 |

Maximum cutting feed rate (m/min) | 20 | |

Machine tool accuracy | Positioning accuracy: X/Y/Z (mm) | 0.008 |

Repeated positioning accuracy: X/Y/Z (mm) | 0.005 | |

Tool magazine | Tool magazine capacity | 24T*2 |

Tool magazine form | Knife arm type knife magazine | |

power source | Air pressure (Mpa) | ≥0.6 |

Electricity demand (Kw) | 27 | |

Other parameters | Dimensions (front and rear * | |

Weight (Approx. weight: Kg) | 7800 | |

Whether to configure network | Have | |

Whether to configure the tool setter | Have |

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Mitsubishi

FANUC

Siemens

SYNTEC

Apr 11 2025

Apr 01 2025