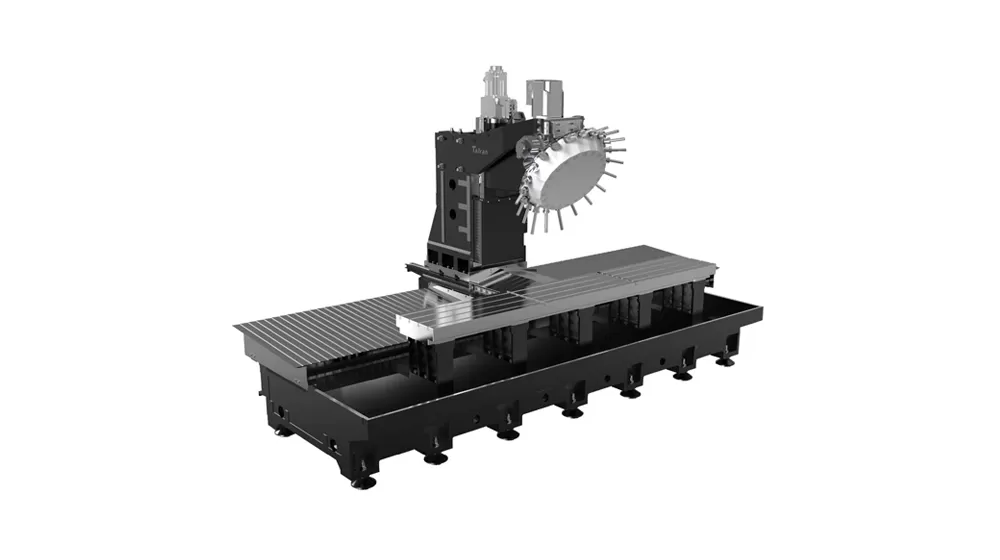

Moving Column Profile Machining Center

BT30 (Tilt-disc Tool Magazine)

Structural Design for Long Workpieces

Fixed table and column-moving structure, specifically designed for large, narrow, and long parts, with a travel range of 2500~6500mm and 50m/min high-speed motion, meeting the high-efficiency processing needs of long workpieces.

Standard welded base, offering low cost and fast delivery, ideal for quick production setup.

Optional cast iron base, providing higher stability and vibration resistance, reducing deformation, and ensuring precision, enhancing overall performance.

High-Performance Feed System

X, Y, Z axes are equipped with high-precision ball linear guides, ensuring high-speed and high-precision feed motion.

X axis uses a gear rack drive system to support high-speed motion over long travels, while also accommodating modular configurations.

Y/Z axes are driven by ball screws, offering excellent rigidity and precision, ensuring stable machining quality.

High-Speed Direct-Drive Spindle

Equipped with a BT30-12000rpm precision spindle, this system provides exceptional high-speed rigidity, ideal for tapping applications. The direct-drive transmission minimizes errors during high-speed tapping, and its high-output force ensures superior performance in high-speed, high-efficiency machining.

BT30 (Tilt-disc Tool Magazine)

High-Speed Servo Tool Change: The PLC-controlled tool change system is optimally designed to shorten tool change time, ensuring fast and stable operation while reducing non-machining time.

Z-Axis Optimization: The optimization improves the rigidity of the Z-axis and significantly enhances its acceleration, reducing the idle travel time.

Widely used in industries such as automotive, 5G, hardware, automotive parts, and home goods. It is primarily designed for processing narrow and long aluminum profiles, and is suitable for the machining of components such as battery trays, transverse rods, longitudinal side panels, sunroof rails, bumpers, and decorative strips.

Workpiece Example 1

Workpiece Example 2

Item | Unit | T-2500 | Remarks | ||

Travel | Table travel (X axis) | mm | 2500 | ||

Saddle travel (Y axis) | mm | 400 | |||

Headstock travel (Z axis) | mm | 350 | |||

Distance from spindle nose to table | mm | 200-550 | |||

Table | Table size | mm | 2650*400 | ||

Max. load | kg | 600 | |||

T-slot (number-width*spacing) | mm | 4-14*100 | |||

Spindle | Motor power (rated/short time) | kW | 3.7/5.5 | ||

Motor torque (rated/short time) | N.m | 23.6/35 | |||

Spindle speed | rpm | 20-12000 | |||

Spindle diameter | mm | Ф100 | |||

Spindle taper | / | BT30 | |||

Speed | Cutting feed speed range | mm/min | 1-10000 | ||

X/Y/Z axis rapid traverse speed | m/min | 50/30/36 | |||

Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.05/0.01/0.01 | GB/T 18400.4 | |

Repeatability (X/Y/Z) | mm | 0.03/0.006/0.006 | (Full travel) | ||

Tool magazine | Tool magazine capacity | T | 21 | ||

Max. tool weight | kg | 3 | |||

Max. tool length | mm | 200 | |||

Max. tool diameter (full /adjacent empty) | mm | Ф60/Ф80 | |||

Others | CNC system | / | Mitsubishi M80VB | ||

Air source | Flow | L/min | ≥200(ANR) | ||

Air pressure | MPa | 0.6-0.8 | |||

Equipment capacity | kVA | 20 | |||

Coolant tank capacity | L | 260 | |||

Machine size | mm | 5270*2640*2450 | Corresponding to X*Y*Z axis | ||

Weight (approx.) | Kg | 6300 | |||

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Mitsubishi

FANUC

Siemens

Apr 11 2025

Apr 01 2025