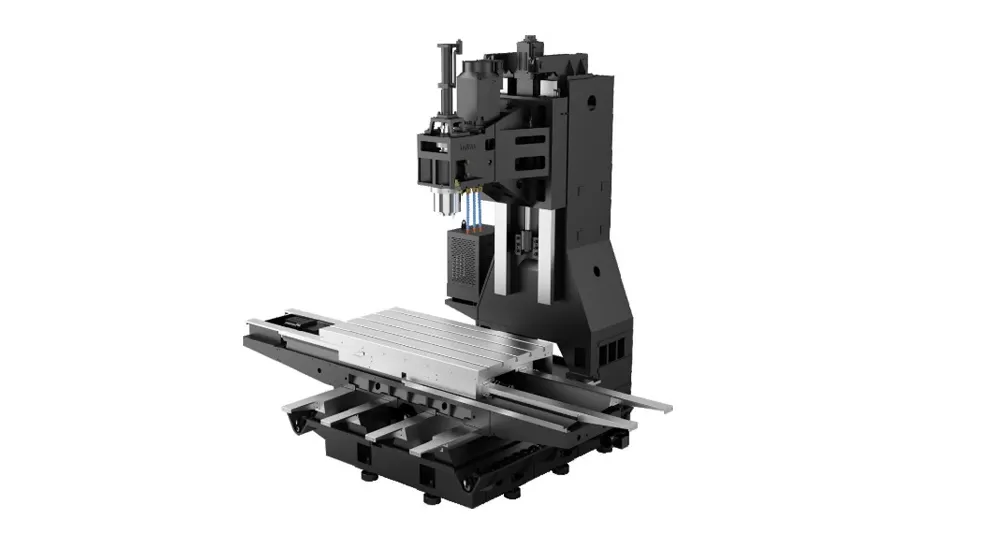

Machine Structure

Fixed column cross-slide structure with an oversized stable base to ensure high load-bearing capacity.

Made of high-strength cast iron, providing excellent rigidity and stable precision.

Three-Axis Box Guideway

The X, Y, and Z axes are equipped with precision-hardened, ground cast iron guideways, with a surface composite bonded with a PTFE (polytetrafluoroethylene) coating.

This design offers high rigidity and excellent shock absorption, making it ideal for heavy cutting of high-hardness mold steel.

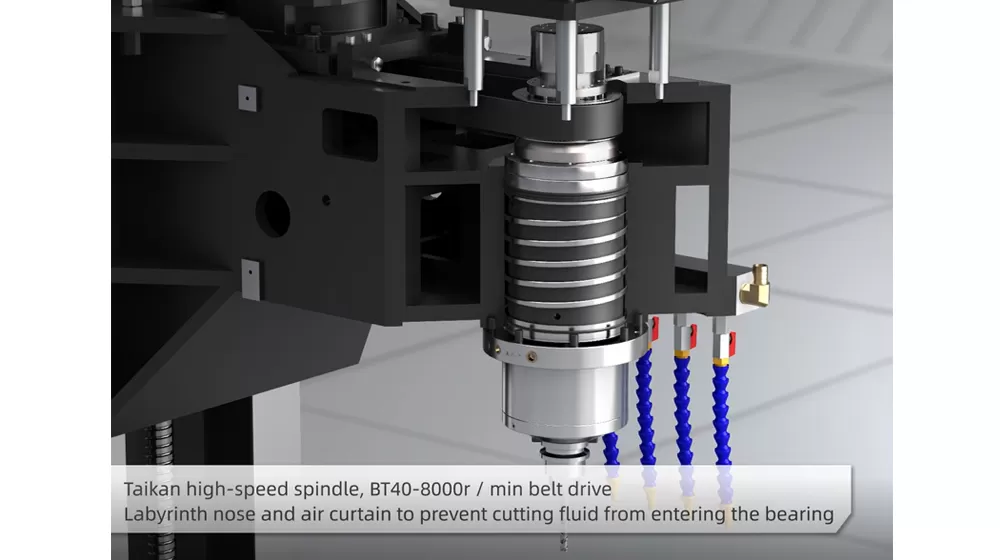

Spindle

High-speed spindle unit (BT50, 8000r/min) with a labyrinth design and air curtain protection, preventing cutting fluid from entering the spindle bearings.

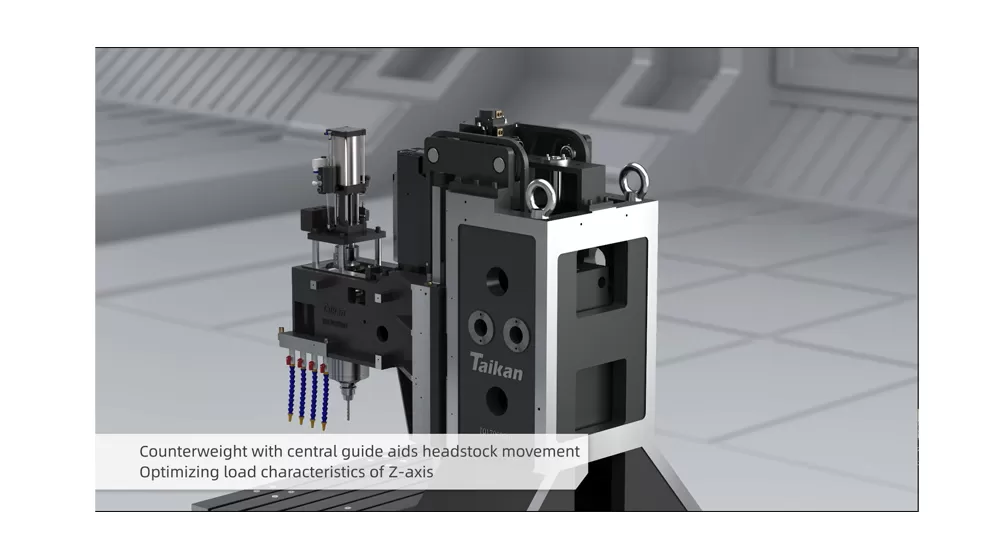

Z-axis Counterweight

Counterweight with central guide aids headstock movement

Optimizing load characteristics of Z-axis

Mainly used in the mold manufacturing industry, it is also widely applicable in aerospace, energy equipment, automotive manufacturing, medical devices, and other industries.

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

Item | Unit | T-18 | Remarks | ||

Travel | Table Travel (X-axis) | mm | 1800 | ||

Saddle Travel (Y-axis) | mm | 900 | |||

Headstock Travel (Z-axis) | mm | 680 | |||

Spindle Nose to Table | mm | 160~840 | |||

Spindle Center to Column | mm | 950 | |||

Table | Table Size | mm | 2000×900 | ||

Table Loading Capacity | kg | 1600 | |||

T-Slots (Qty-Width×Pitch) | mm | 5-22×165 | |||

Spindle | Motor Power (Cont./30min) | kW | 18.5/22 | ||

Speed Range | rpm | 50~8000(Belt-driven) | |||

Spindle Diameter | mm | φ190 | |||

Tool Holder Type | – | BT50 | |||

Pull Stud Type | – | P50T-I(MAS403) | |||

Speed | Feed Rate Range | mm/min | 1-10000 | ||

Rapid Traverse Speed(X/Y/Z) | m/min | 41255 | |||

Accuracy | Positioning Accuracy(X/Y/Z) | mm | 0.024 | GB/T18400.4 (Full Travel) | |

Repeatability(X/Y/Z) | mm | 0.012 | |||

Other | CNC System | – | Mitsubishi M80VA | ||

Air Supply | Flow | L/min | ≥280 (ANR) | ||

Pressure | MPa | 0.6~0.8 | |||

Power Requirement | kVA | 45 | |||

Coolant Tank Capacity | L | 400 | |||

Machine Dimensions | mm | 4850×3500×3500 | X/Y/Z axis directions | ||

Machine Weight(approx.) | kg | 14750 | |||

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Mitsubishi

FANUC

Siemens

Taikan

Apr 11 2025

Apr 01 2025