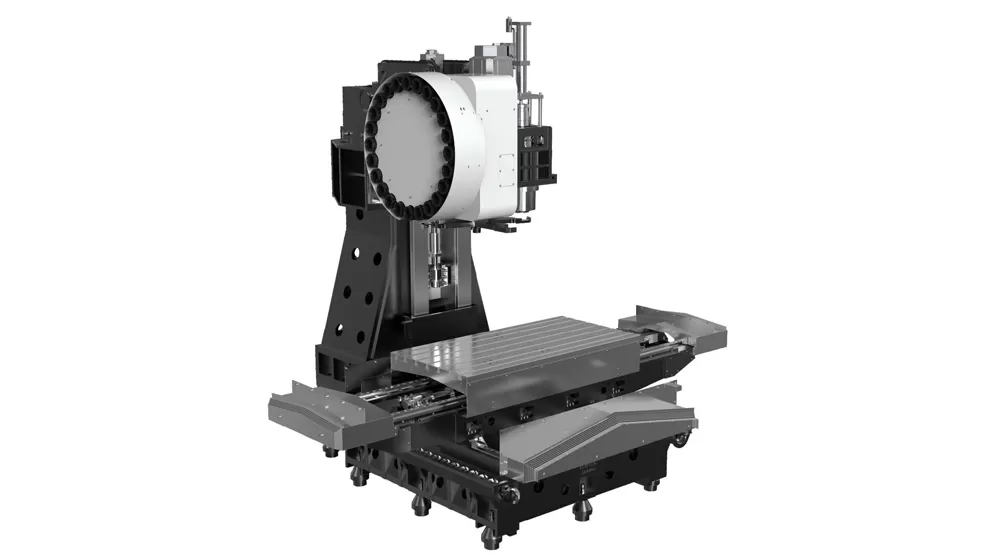

Two Linear Rails and One Boxway

High precision and high efficiency - An outstanding masterpiece

Machine Structure and Design

Column-type Cross-slide Structure: The Y-axis adopts a four-rail design, providing excellent high-load capacity and precise machining performance.

High-strength Cast Iron Components: The major base parts are made from resin sand casting and high-strength cast iron, ensuring exceptional rigidity and long-term precision stability.

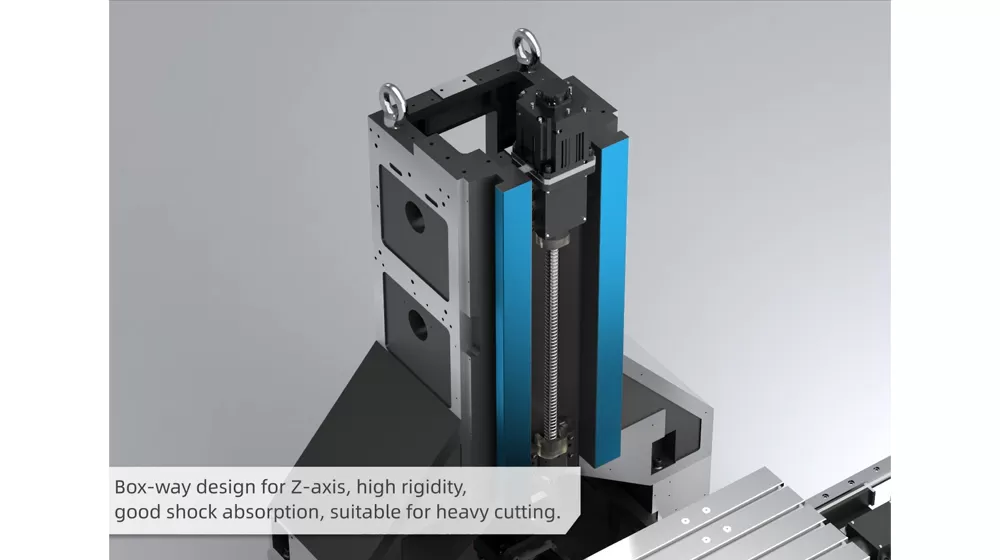

High-rigidity Feed System

High-rigidity Rails: The X/Y axes use linear rails, offering low friction and noise, while the Z-axis uses rectangular hardened rails, capable of bearing greater cutting forces with strong vibration resistance.

Pre-stretched Ball Screws: The ball screws are pre-stretched during installation, further enhancing transmission accuracy and stability, ensuring high-precision machining.

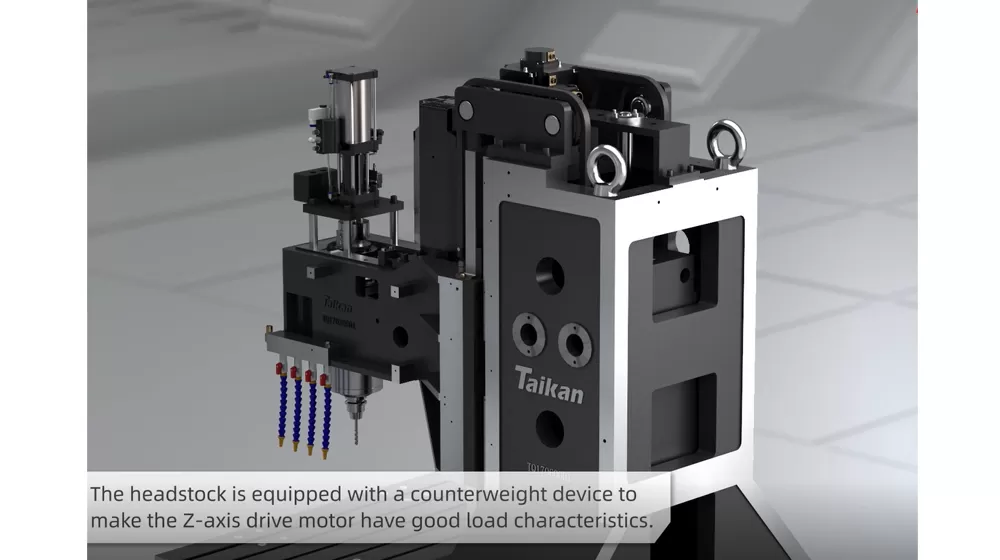

Z-axis Balancer System

Balancer Device: The Z-axis spindle box is equipped with a balancer device, ensuring smooth movement at high speeds and improving machining stability and accuracy.

Precise Counterweight Design: The counterweight is precisely matched to the spindle box's weight, optimizing the load characteristics of the Z-axis drive motor for the best machining performance.

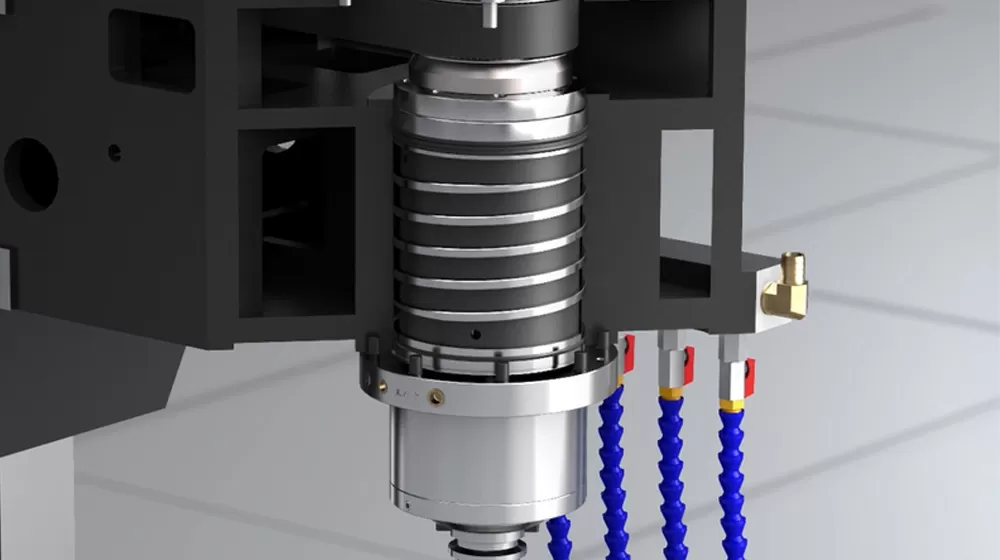

High-efficiency Spindle System

Belt-driven Spindle: The machine comes standard with a Taikan high-speed BT50 belt-driven spindle, with a maximum speed of 6000rpm, significantly improving cutting efficiency.

Spindle Protection: The front of the spindle features a labyrinth design and air curtain protection, effectively preventing cutting fluids from entering the spindle bearings, prolonging service life, and reducing maintenance costs.

Constant Temperature Cooling System: The spindle is equipped with central air blow and an automatic water-cooling system, maintaining a stable temperature and reducing thermal deformation, ensuring sustained high-precision machining.

Workpiece Example 1

Workpiece Example 2

Item | Unit | T-1375L | Remarks | ||

Travel | Table travel (X axis) | mm | 1350 | ||

Saddle travel (Y axis) | mm | 750 | |||

Headstock travel (Z axis) | mm | 750 | |||

Distance from spindle nose to table surface | mm | 120~870 | |||

Distance from spindle center to column guide surface | mm | 810 | |||

Table | Table size | mm | 1500*750 | ||

Max. load (even load-bearing) | kg | 1300 | |||

T-slot (number of slots - slot width * spacing) | mm | 5-18*150 | |||

Spindle | Motor power (rated/short time) | kW | 15/18.5 | ||

Motor torque (rated/short time) | N.m | 143/191 | |||

Speed range | r/min | 50~6000(belt) | |||

Spindle diameter | mm | Φ190 | |||

Spindle taper | / | BT50 | |||

Rivet specifications | / | P50T-I(MAS403) | |||

Speed | Cutting feed speed range | mm/min | 24 | ||

X/Y/Z axis rapid traverse speed | m/min | 15 | |||

Tool magazine | Tool capacity | mm | 300 | ||

Max. tool weight | mm | Φ105/Φ210 | |||

Max. tool length | pcs | 1-10000 | |||

Max. tool diameter (full /adjacent empty) | kg | 24/24/15 | |||

Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.015 | GB/T18400.4 (Full travel) | |

Repeatability (X/Y/Z) | mm | 0.008 | |||

Others | Z-axis counterweight | Counterweight | |||

CNC system | / | FANUC 0i-MF Plus | |||

Air source | Flow | L/min | 280(ANR) | ||

Air pressure | MPa | 0.6~0.8 | |||

Equipment capacity | KVA | 35 | |||

Coolant tank capacity | L | 400 | |||

Machine size | mm | 5050×3680×3550 | With chip conveyor pedal | ||

Weight (approx.) | Kg | 11200 | |||

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Mitsubishi

FANUC

Siemens

Taikan

Apr 11 2025

Apr 01 2025