01

Single Spindle, Single System

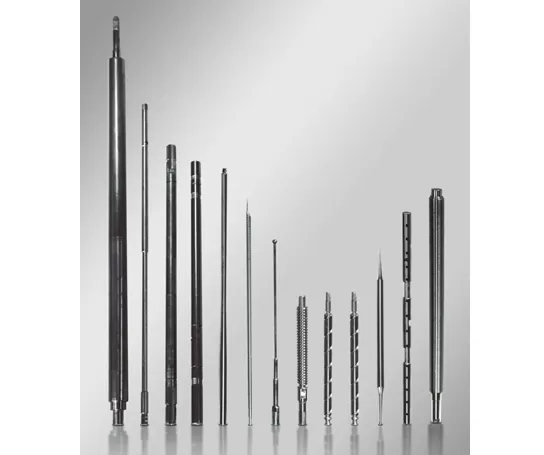

3 Linear Feed Axes, 32m/min Rapid Traverse Speed

Standard Equipment Includes 5 Driven Tool Holders

Spindle Without Side Milling Driven Tool Option

02

Built-in motorized spindle

03

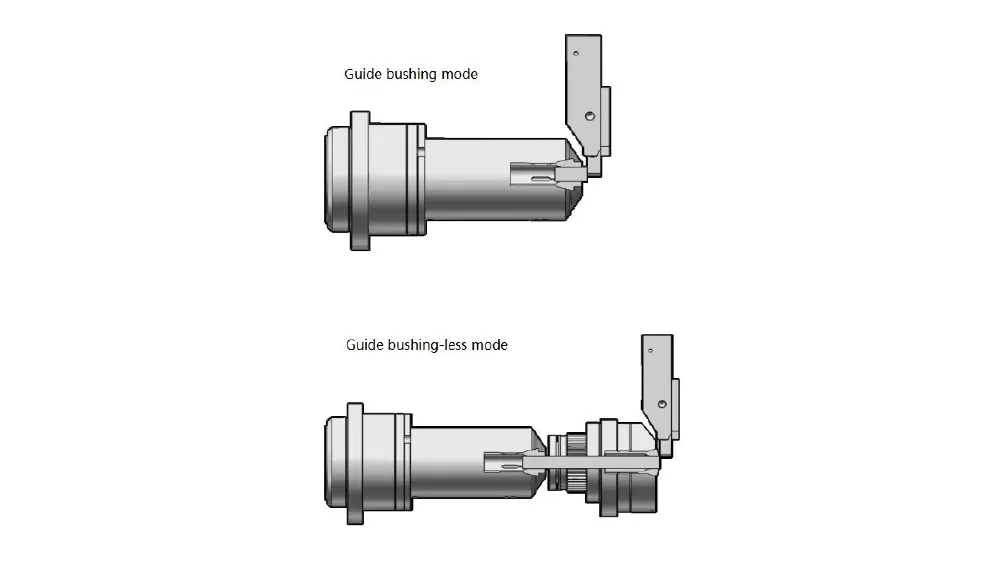

Interchangeable with and without guide sleeve

Mitsubishi system secondary development. cold and hot machine compensation

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

Workpiece Example 5

Item | ST-203Ⅰ |

Max. Processing Diameter | Ø20 |

Max. Processing Length | 240 mm |

Front Drilling Diameter | Max. Ø10 |

Front Thread Processing | Max. M8 |

Spindle Through Hole Diameter | 23 mm |

System Device | Mitsubishi E80 |

Spindle Speed | Max. 8000 r/min |

Turning Tool | 5×□12 + 1×□16 |

End Fixed Tool Holder | 5×ER16 |

Movement Speed | 32 m/min (Y), 20 m/min (X), 24 m/min (Z) |

Spindle Motor Power | 3.7 kW / 5.5 kW |

Feed Motor Power | 1.0 kW (X/Y/Z) |

Total Machine Power | 8 kW |

Total Machine Weight | 1800 kg |

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Mitsubishi

FANUC

SYNTEC

High-Pressure Oil Pump

Oil Mist Collector

Chip Conveyor

Auto Feeder

Apr 11 2025

Apr 01 2025