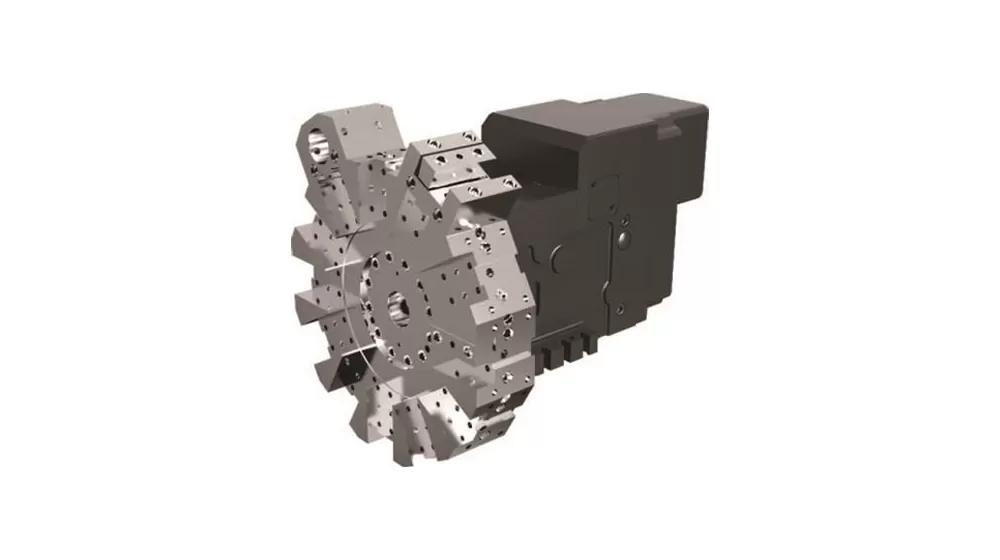

T-type gang tool with versatile tool arrangement combinations.

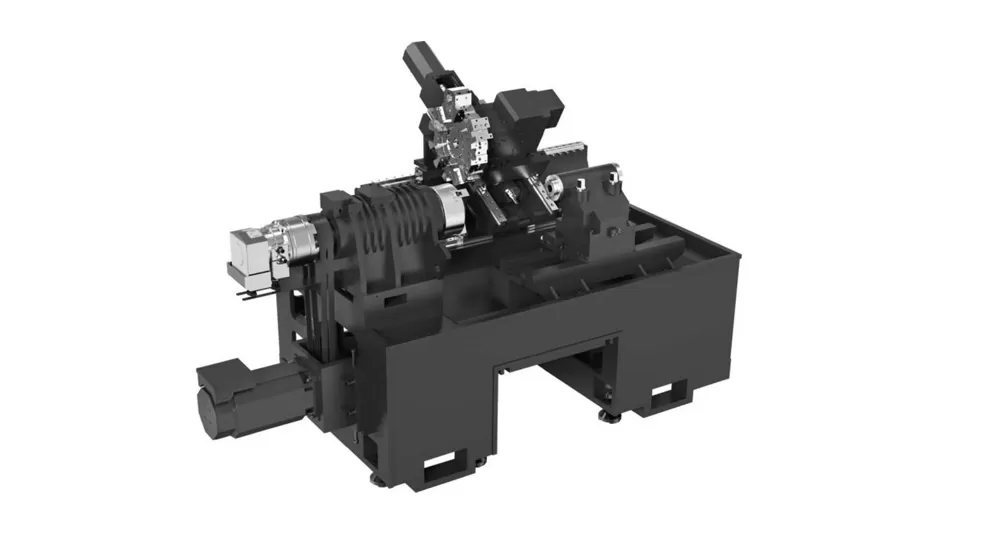

Overall

The CNC lathe adopts a box-type bed structure, high-strength HT300 cast iron, dense structure, good strength, appropriate hardness, low friction coefficient, and self-lubricating property. The base bed has an integral box structure, which greatly enhances the overall rigidity and stability of the machine tool, and has the function of absorbing vibration, reducing tool wear and improving workpiece quality.

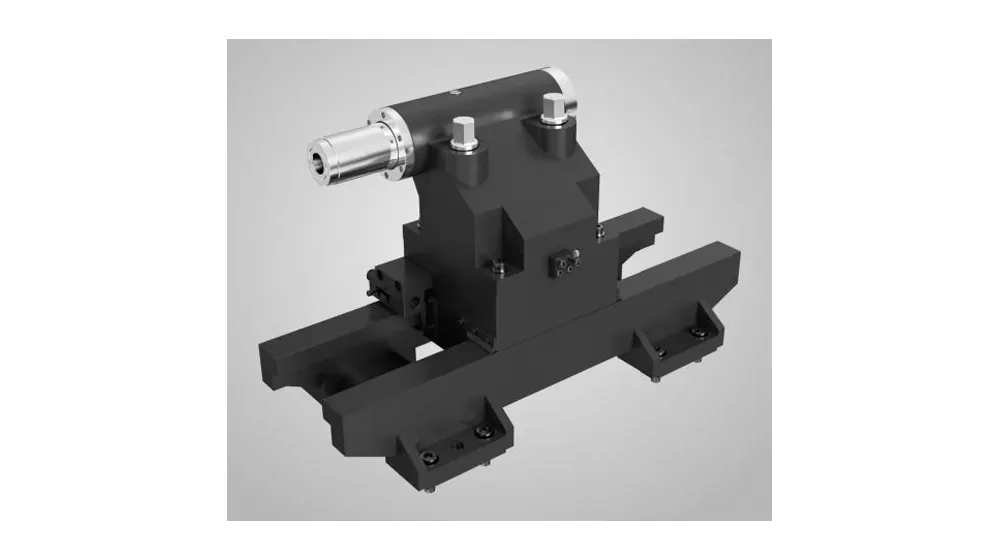

Hydraulic Sleeve Tailstock

The large span hard rail structure design is of high rigidity, strong performance and strong bearing capacity. The dovetail structure makes the lower pressure plate more reliable when locked.

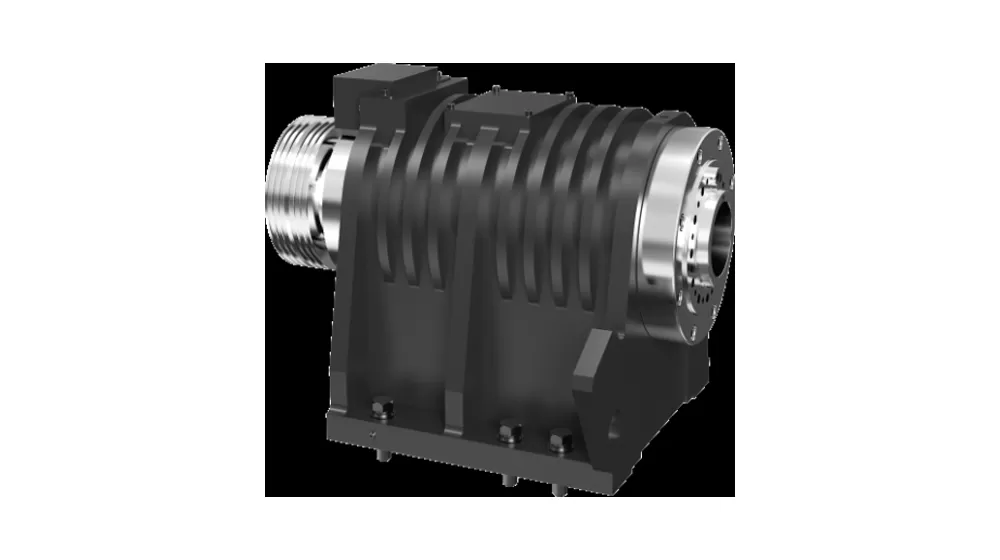

Spindle

The machine adopts an integral sleeve spindle, imported precision spindle bearings, and spindle servo motor drive to achieve high precision, high rigidity, and speed stability.

The heat sink-type spindle box design is equipped with symmetrical reinforcement ribs to effectively reduce the spindle temperature rise, increase spindle stability, and increase bearing life.

Tool

Use full gang tool.

This lathe can be widely used in instruments, meters, light industry, electronics, medical equipment, film machinery and other industries for processing single pieces, small batches and large batches. It is especially suitable for processing small non-ferrous metal parts and shafts and discs with complex shapes.

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

Name | Unit | L-P36G | Remarks | |

Machining range | Max. swing diameter on the bed slide | mm | Φ420 | |

Max. machining length | mm | 330 | ||

Machining diameter (disc type) | mm | Φ300 | ||

Machining diameter on the cutter | mm | Φ125 | ||

Travel | X-axis travel | mm | 900 | |

X-axis motor power/stall torque | kW/Nm | 1.2/7 | ||

Z-axis travel | mm | 330 | ||

Z-axis motor power/stall torque | kW/Nm | 1.2/7 | ||

Spindle | Output power (S1/S2) | kW | 3.7/5.5 | |

Spindle end type | A2-4 | |||

Spindle speed | r/min | 0-6000 | ||

Spindle through hole diameter/bar diameter | mm | Φ46/Φ35 | ||

Fixture | Hollow collet | inch | 5 | |

Speed | Rapid traverse speed (X axis) | m/min | 30 | |

Rapid traverse speed (Z axis) | m/min | 30 | ||

Cutting feed rate | mm/min | / | ||

Tool holder | Tool holder type | full gang tool | ||

Quantity | PCS | 7 | ||

Cutter body size | mm | 20´20 | ||

Max. boring tool diameter | mm | 20 | ||

Accuracy | Positioning accuracy (X axis) | mm | 0.003 | |

Positioning accuracy (Z axis) | mm | 0.003 | ||

Repeatability ((X axis) | mm | 0.002 | ||

Repeatability ( (Z axis) | mm | 0.002 | ||

Othes | Equipment capacity | kVA | 10 | |

Coolant tank capacity | L | 100 | ||

Machine size | mm | 2100´1600´1950 | ||

Weight (approx.) | kg | 2650 | ||

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Mitsubishi

FANUC

Siemens

SYNTEC

Apr 11 2025

Apr 01 2025