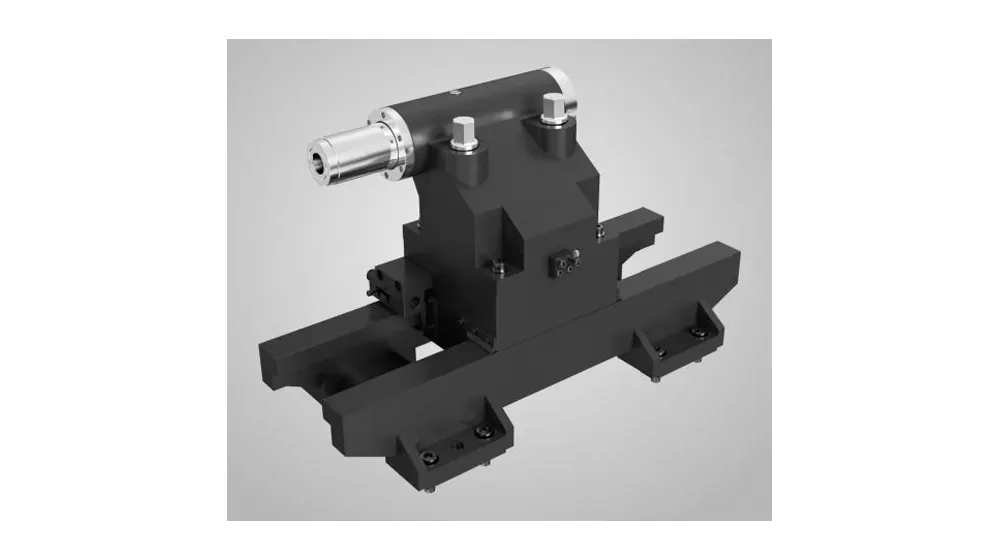

T-type gang tool with versatile tool arrangement combinations.

Overall

This machine tool has an integrated mechanical, electrical and hydraulic layout, adopts a fully enclosed protective cover, the protective door opens to the left, and the CNC operation panel is located on the top of the fixed protective cover, which is easy to operate.

The large basic parts are all made of high-quality resin sand molding and high-strength cast iron materials, which gives the machine tool high rigidity and stable precision.

Hydraulic Sleeve Tailstock

The large span hard rail structure design is of high rigidity, strong performance and strong bearing capacity. The dovetail structure makes the lower pressure plate more reliable when locked.

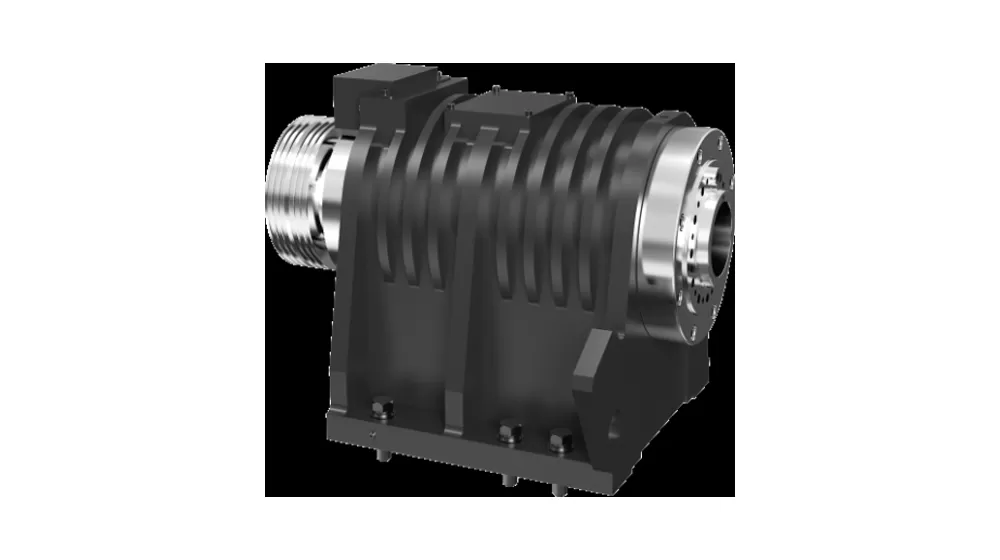

Spindle

The main transmission system of this machine tool is driven by a high-performance servo motor, which drives the spindle through a belt. The spindle speed range is 0-6000r/min.

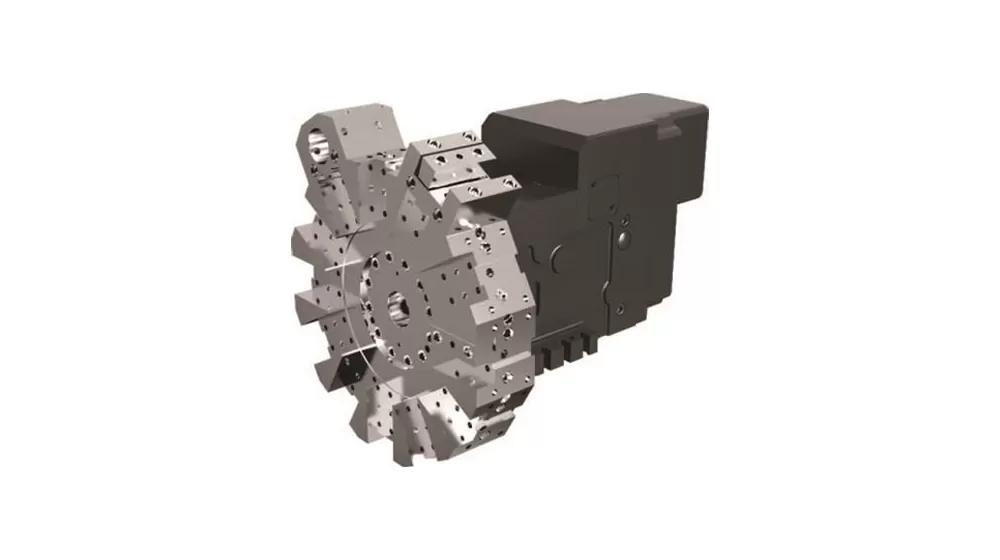

Tool

Use gang tool.

This machine can automatically complete the turning of cylinders, cones, stepped shafts, arc surfaces, end faces, grooving, drilling and various metric and inch straight and tapered threads. The machine is equipped with a series of spring chucks, which can be widely used in instruments, meters, light industry, electronics, medical equipment, film machinery and other industries.

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

Name | Unit | L-P20G | Remarks | |

Machining range | Max. swing diameter on the bed slide | mm | φ240 | |

Max. swing diameter on the tool base | mm | Φ120 | ||

Max. turning length | mm | 100 | ||

Max. turning diameter | mm | φ100 | ||

Max. clamping diameter of spring chuck | mm | φ20 | ||

Travel | X-axis travel | mm | 280 | |

X-axis motor power/stall torque | kw/Nm | 1/3.2 | ||

Z-axis travel | mm | 180 | ||

Z-axis motor power/stall torque | kw/Nm | 1/10 | ||

Spindle | Spindle clamping type | kw | Type 20 collet chuck | |

Spindle head type | Non-standard | |||

Spindle through hole diameter | φ26 | |||

Spindle maximum speed | 0-6000 | |||

Spindle motor torque (rated/maximum | r/min | 17.7/26.5 | ||

Spindle motor (S1/S2) | mm | 3.7/5.5 | ||

Fixture | Spring chuck | inch | Φ20 | |

Speed | Rapid traverse speed (X axis) | m/min | 18 | |

Rapid traverse speed (Z axis) | m/min | 18 | ||

Cutting feed speed | mm/min | |||

Tool holder | Tool holder type | Gang tool | ||

Tool indexing time | Seconds/bit | / | ||

Tool body size | mm | 16´16 | ||

Max. boring tool diameter | mm | 25 | ||

Accuracy | Positioning accuracy (X axis) | mm | <0.01 | |

Positioning accuracy (Z axis) | mm | <0.01 | ||

Repeatability ((X axis) | mm | 0.002 | ||

Repeatability ( (Z axis) | mm | 0.002 | ||

Other | Equipment capacity | kVA | 6 | |

Coolant tank capacity | L | 50 | ||

Machine size | mm | 1275×1408×1532 | Manual chip removal coolant tank | |

Weight (approx.) | kg | Approx. | ||

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Mitsubishi

FANUC

Siemens

SYNTEC

Apr 11 2025

Apr 01 2025