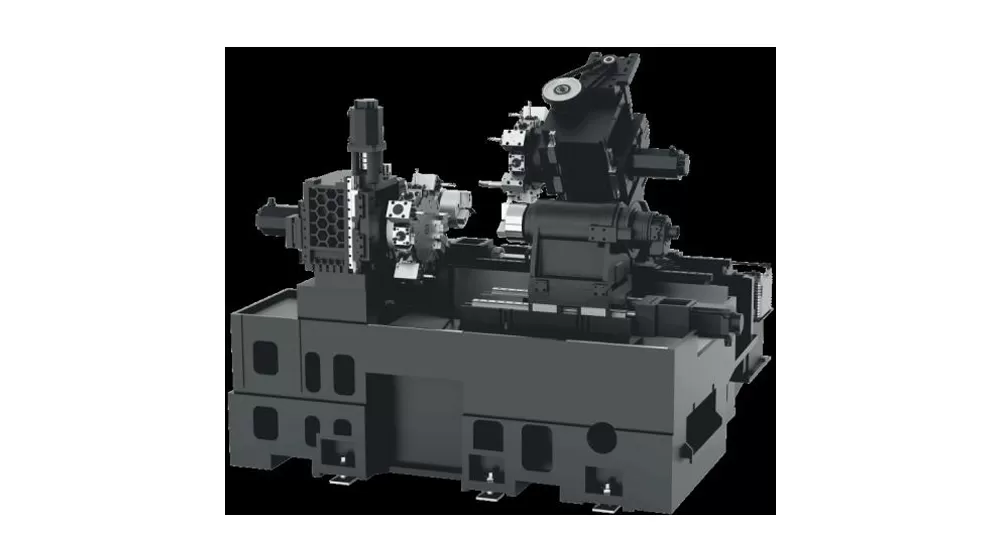

CNC Horizontal turning(milling) compound with Y axis

Powerful technology, one machine with multiple functions, multiple varieties, small batches

Overall

Dual-spindle and dual-turret CNC turning and milling machine tool

Fully enclosed protection, single left sliding door, optional automatic discharge device, independent chip collection water tank, automatic chip conveyor, good chip removal performance

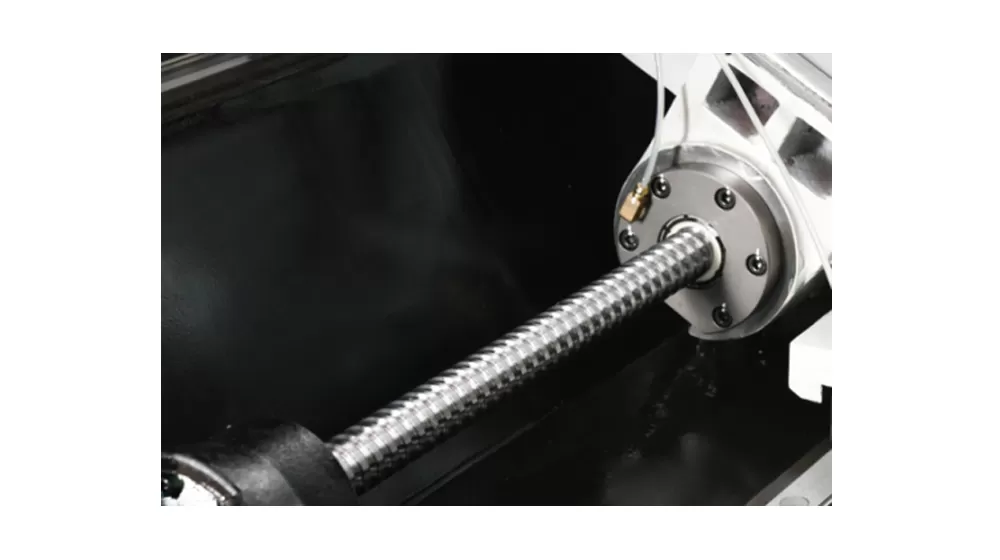

Guide Rail

Adopt Japanese THK or Taiwan PMI linear rolling or roller guide rails, Japanese THK or Taiwan PMI ball screw drive. Good dynamic characteristics, high precision and strong rigidity.

It adopts preloaded linear roller guide and ball screw, which has the characteristics of fast speed and high processing precision.

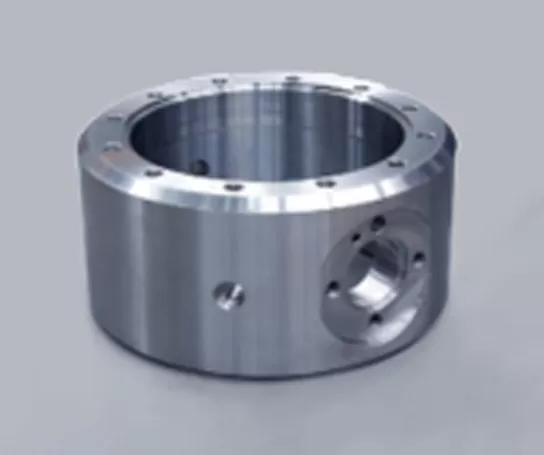

Spindle

The permanent magnet synchronous electric spindle has good dynamic characteristics, high precision and strong rigidity.

Synchronous servo electric spindle has high precision, fast acceleration and deceleration, and saves energy.

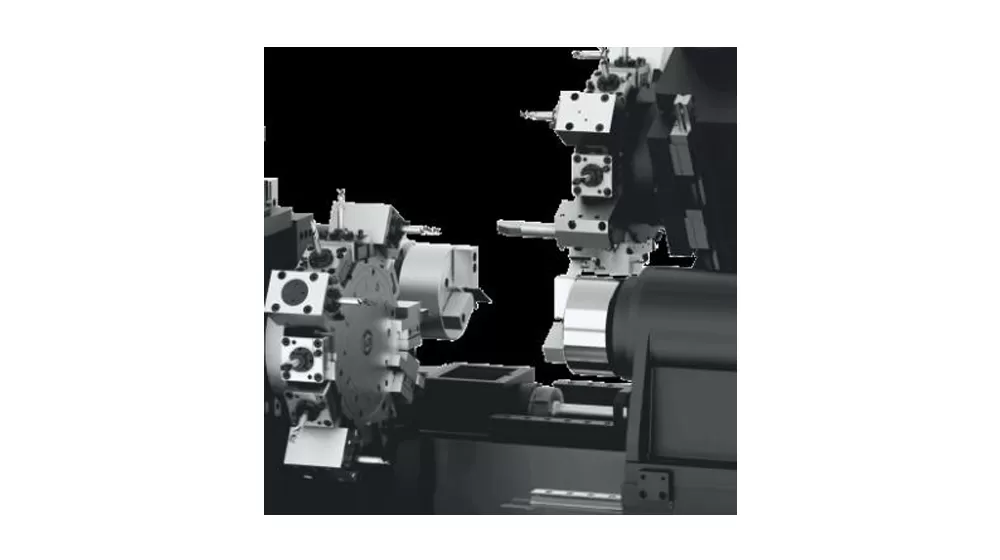

Tool

Relying on the servo lifting power turret, it has high precision and fast tool change speed, can complete complex processing requirements, and can replace machining centers and engraving machines.

It can process workpieces with diameters of 20-130 mm and lengths of 2.5-130 mm; the maximum rotation diameter of the saddle is 320 mm. It can process short shaft (or disc) parts with complex geometric shapes, various sizes, and high precision requirements.

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

Item | Unit | L-46SDY | |

Machining range | Max. swing diameter on the bed | mm | Φ570 |

Max. turning diameter on the saddle | mm | Φ320 | |

Max. turning diameter | mm | Φ130 | |

Max. turning length | mm | 130 | |

Travel | X1, X2 axis travel | mm | 200、300 |

Y1 axis travel | mm | ±50 | |

Y1 effective machining travel | mm | ±45 | |

Z1, Z2 axis travel | mm | 320、300 | |

Main/Sub-spindle | Chuck size | inch | 6" |

Max. speed | rpm | 6000 | |

Basic speed | rpm | 2000 | |

Spindle end type | A2-5 | ||

Spindle through hole size | mm | Φ57 | |

Motorized spindle power | Kw | 15/17.8 | |

Adjustable bar diameter | mm | Φ45 | |

Milling spindle | Max. speed | rpm | 4000 |

Drilling capacity | mm | Φ16×1.5 | |

Tapping capacity | [mm] x | M12x1.75 | |

[mm] | |||

Milling spindle motor | KW | 2.7 | |

Turret interface | BMT45 | ||

Feed speed | X-axis rapid traverse speed | mm/min | 18000 |

Z-axis rapid traverse speed | mm/min | 18000 | |

Y-axis rapid traverse speed | mm/min | 10000 | |

Motor | Spindle motor | KW | >11 |

Cooling pump motor | KW | 0.75 | |

Electricity/Air source | Power supply capacity (continuous fixed rate) | KVA/Kw | 64KVA/44.75KW |

Air source | L/min | 0.5Mpa/100 | |

cooling | Water tank capacity | L | 130 |

Size/weight | Distance from spindle center to ground | mm | 1070 |

Machine height | mm | 2060 | |

| mm×mm | 2410 (without chip conveyor) × 2210 | |

Machine weight (approx.) | Kg | 5000 | |

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Mitsubishi

FANUC

Siemens

SYNTEC

Apr 11 2025

Apr 01 2025