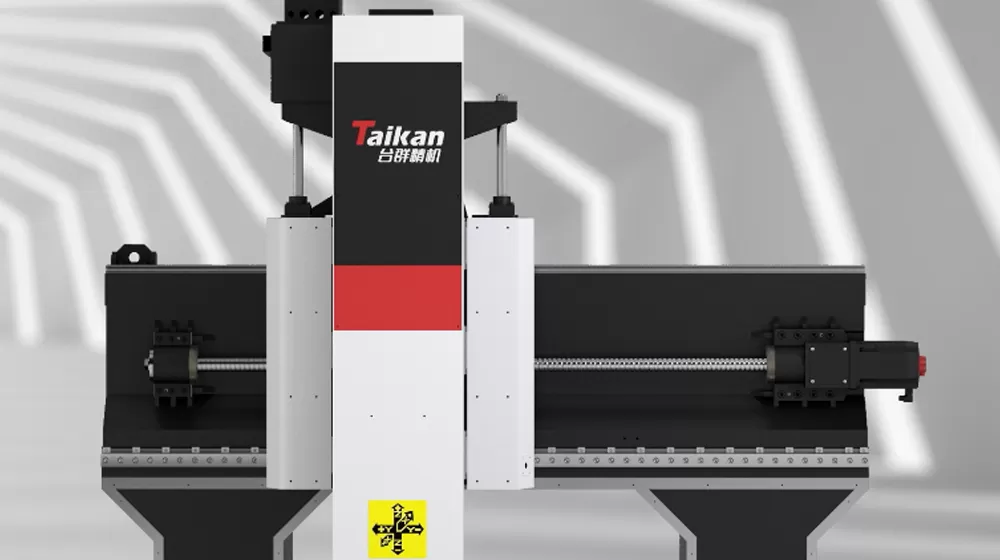

Fixed Beam 5-Axis Simultaneous

Gantry Machining Center

Gantry Configuration

The machine adopts a gantry-fixed structure with table-moving configuration, providing optimal stability for efficient cutting operations.

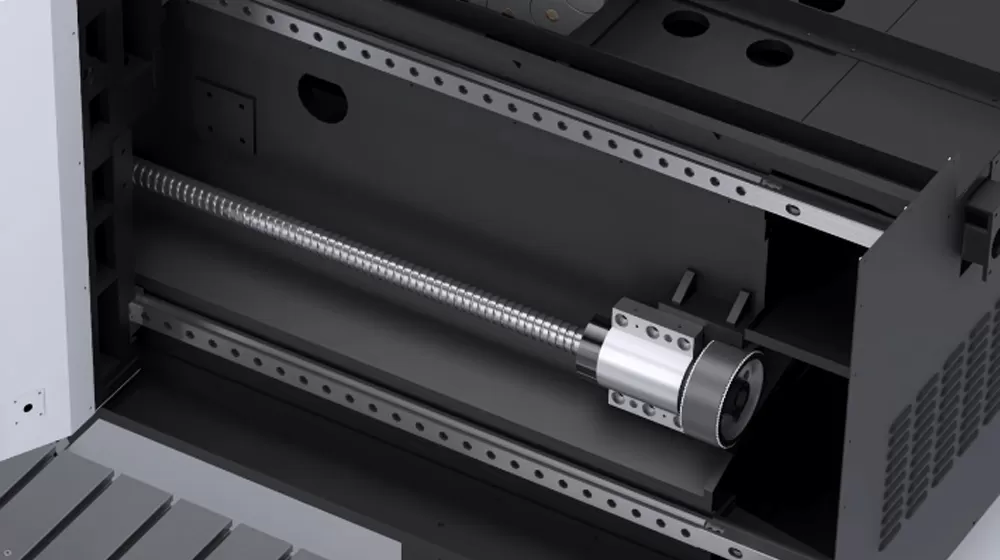

Stepped Guide Rails

The beam guide rails are arranged in a stepped layout, increasing the guide rail span and improving load-bearing capacity, ensuring good load-bearing performance and stable cutting during machining.

Nitrogen Balancing

The Z-axis uses a nitrogen balancing cylinder to balance the weight of the ram.

Spindle Unit

The spindle unit uses a Zhongke Ibeg T70.5 5-axis linked A/C double swivel milling head, which can achieve 5-axis linked machining of complex surfaces.

With high-precision encoders and a hydraulic clamping system, the A and C axes can be clamped at any angle within their operating range (C axis ±360°, A axis ±110°).

Standard 18000rpm motorized spindle, capable of high-precision, fast, and continuous cutting.

Primarily used for machining complex parts, aluminum and its alloys, as well as difficult-to-machine materials. It is capable of high-precision and high-efficiency machining of complex spatial surfaces.

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Item | Unit | G-VU1530 | Remarks | ||

Travel | Table travel (X-axis) | mm | 3200 | ||

Saddle travel (Y-axis) | mm | 2700 | |||

Ram travel (Z-axis) | mm | 1000 | |||

Spindle nose to table distance | mm | 100~1100 | |||

Spindle overhang | mm | 329.2 | |||

Effective gantry width | mm | 2450 | |||

Table | Table size | mm | 1500*3000 | ||

Max. load | Kg | 10000 | |||

T-slot | mm | 28 | |||

Spindle | Spindle power | KW | 30 | ||

Max. speed | r/min | 18000 | |||

Torque output | Nm | 72Nm-S1, 85Nm-S6 | |||

Spindle taper | HSK-A63 | ||||

A-axis swing angle | ±110° | ||||

C-axis rotation | ±360° | ||||

A/C-axis max. speed | rpm | 60 | |||

Speed | Feed rate range (Cutting) | mm/min | 10000/10000/10000 | ||

Rapid traverse speed (X/Y/Z-axis) | mm/min | 15000/15000/15000 | |||

Accuracy | Positioning accuracy(With scale) | mm | 0.023/0.021/0.014 | Standard Fagor Linear Scale | |

Repeatability(With scale) | mm | 0.015/0.013/0.011 | Standard Fagor Linear Scale | ||

A-axis Positioning accuracy | 8″(VD13441) | ||||

A-axis Repeatability | 4″(VD13441) | ||||

C-axis Positioning accuracy | 8″(VD13441) | ||||

C-axis Repeatability | 4″(VD13441) | ||||

Others | Z-axis counterweight | Hydraulic + nitrogen balance | |||

CNC system | SIEMENS ONE | 5-axis simultaneous control | |||

Air supply | Flow | L/min | 500 | ||

Pressure | MPa | 0.6~0.8 | |||

Coolant tank capacity | L | 750 | |||

Machine size(L×W×H) | mm | 7800*6100*6000 | |||

Machine Enclosure | set | Full perimeter sheet metal | No top cover | ||

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Siemens

Apr 11 2025

Apr 01 2025