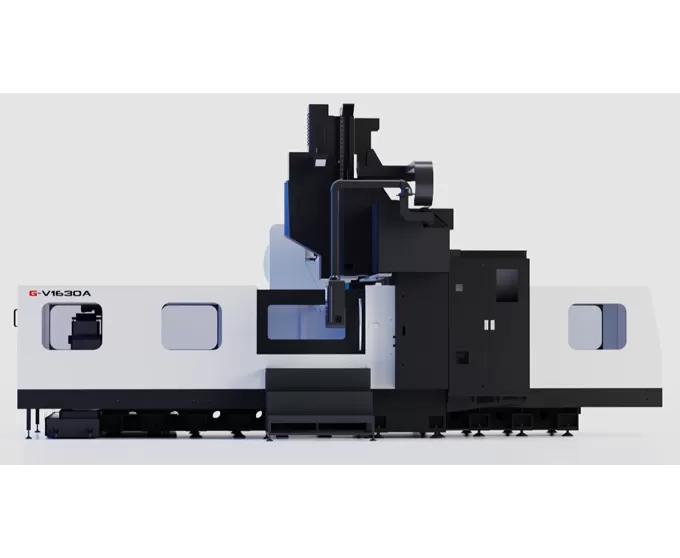

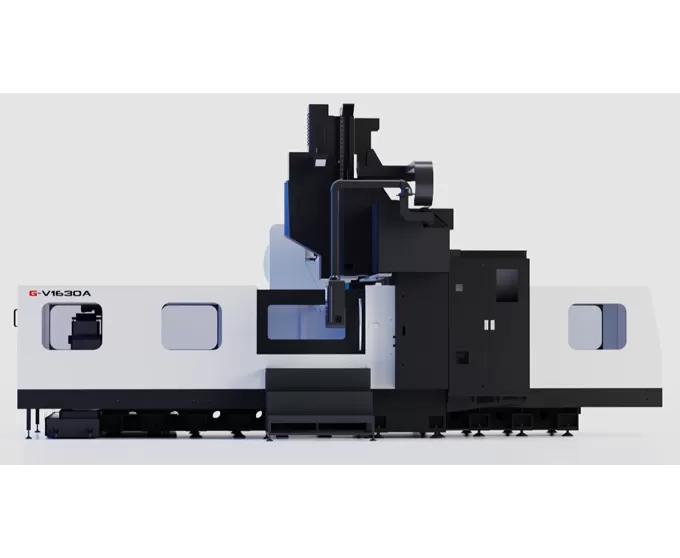

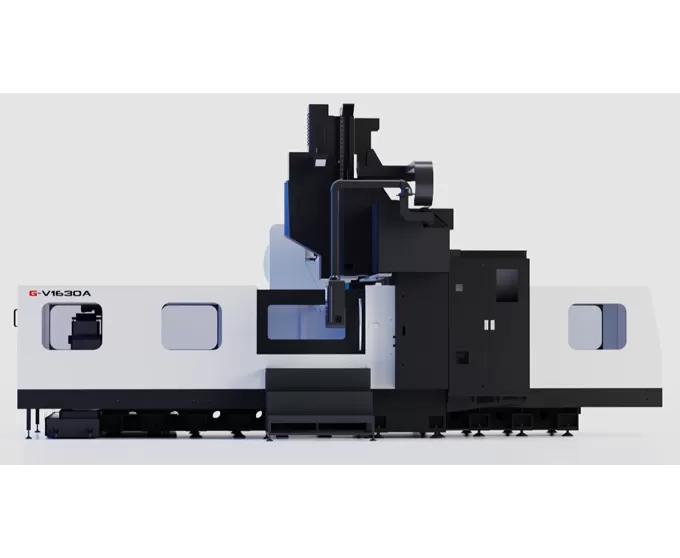

Three-Axis Linear Guide Gantry Machining Center

The machine is suitable for the multi-variety and small-to-medium batch processing of complex parts such as medium-sized box-type components, plates, discs, valves, and housings.

| Item | Unit | G-V1630A | G-V1630B | G-V1630C | ||

| Travel | X-axis travel (Table longitudinal) | mm | 3200 | |||

| Y-axis travel (Crossbeam transverse) | mm | 1800 | ||||

| Z-axis travel (Ram vertical) | mm | 800 | ||||

| Distance from spindle end to table | mm | 100~900 | 70~870 | |||

| Effective gantry width | mm | 1800 | ||||

| Table | Table size (L×W) | mm | 3000×1600 | |||

| Max. load | kg | 8000 | ||||

| T-slot (Width×Pitch×Qty) | mm | 22×160×9 | ||||

| Spindle | Drive type | / | Belt driven | Gear driven | Motorized spindle | |

| Max. spindle speed | r/min | 6000 | 6000 | 15000 | ||

| Spindle power (Rated/Peak) | kW | 15/18.5 | 15/22 | |||

| Torque output (Rated/Peak) | N.m | 191/315 | 573/945 | 45.7/73.6 | ||

| Spindle taper | / | BT50 | BBT40 | |||

| ATC (Opt.) | Number of tools | T | 24 | |||

| Max. tool dia. (Full/Adjacent) | mm | Φ110/Φ200 | Φ80/Φ150 | |||

| Max. tool length | mm | 350 | 250 | |||

| Max. tool weight | kg | 18 | 8 | |||

| Speed | Feed rate range (Cutting) | m/min | 10 | |||

| Rapid traverse speed (X/Y/Z-axis) | m/min | 16/16/12 | ||||

| Accuracy | Positioning accuracy | mm | 0.02/0.015/0.012 | |||

| Repeatability | mm | 0.012/0.008/0.008 | ||||

| Others | Z-axis counterweight | / | Nitrogen balance | |||

| CNC system | / | FANUC 0i-MF PLUS (Opt. Mitsubishi M80, Siemens 828D) | ||||

| Air supply | Flow | L/min | 280 (ANR) | |||

| Pressure | MPa | 0.5~0.8 | ||||

| Total electrical capacity | kVA | 40 | ||||

| Coolant tank capacity | L | 400 | ||||

| Machine size | Length | mm | 7800 | |||

| Width | mm | 5400 | ||||

| Height | mm | 4550 | ||||

| Machine Enclosure | - | Full perimeter sheet metal | ||||

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

FANUC

Siemens

Mitsubishi

Apr 11 2025

Apr 01 2025