Three-Axis Linear Guide Gantry Machining Center

Machine Structure

Integrated Design: The machine features a gantry-type structure with an integrated column and crossbeam, enhancing overall rigidity.

Z-Axis Balance System: Utilizes nitrogen pressure to counterbalance the weight of the spindle box and ram, reducing the load on the servo motor. This minimizes vibration and deformation, improving machining accuracy and stability. Additionally, it reduces mechanical wear, extending the machine’s service life.

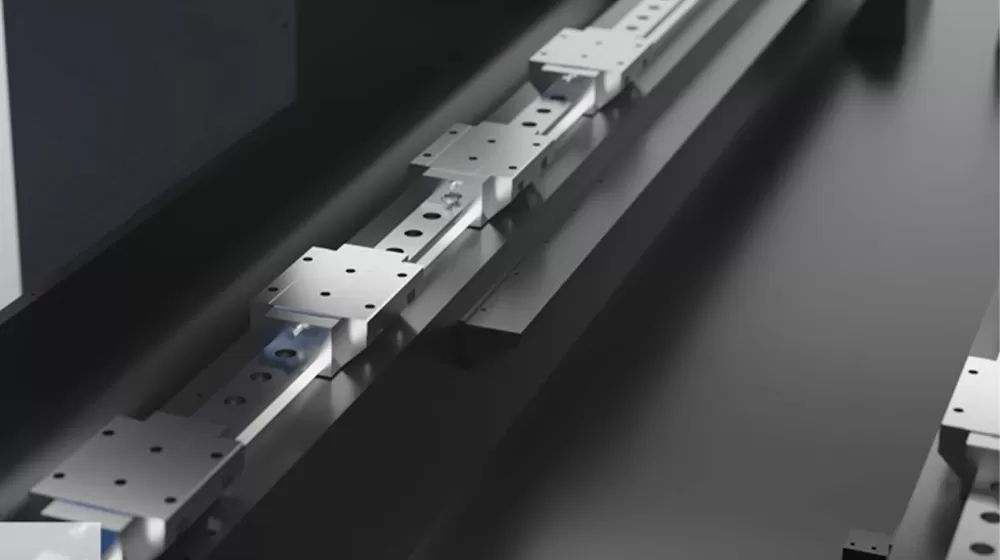

3-Axis Motion System

3-Axis Guideway: Adopts a roller-type linear guide design, providing fast dynamic response and high precision, ensuring smooth operation without creeping.

Drive System: The servo motor is directly coupled with a high-precision ball screw, combined with a fixed pre-tensioned structure at both ends, achieving high transmission accuracy and stability.

Diversified Spindle Lineup

Belt-driven Spindle: Utilizes a BT50-6000rpm high-speed spindle unit, offering high cutting efficiency.

Gear-driven Spindle: BT50-6000rpm spindle unit paired with a gearbox for heavy cutting demands. The gearbox features an oil cooling function to reduce spindle thermal deformation, ensuring high cutting efficiency.

Motorized Spindle: High-frequency motorized spindle with a maximum speed of 15,000 r/min. It is equipped with a coaxial ring encoder for synchronous feedback of spindle speed and angle, offering rigid tapping functionality and excellent high-speed performance.

Coolant Prevention: The spindle's front end incorporates a labyrinth seal structure and an air curtain protection system, effectively preventing coolant from entering the spindle bearings and extending service life.

Thermal Control: Equipped with a central air-blow function and an automatic circulation cooling system, significantly reducing temperature rise and thermal deformation, ensuring high machining accuracy and stability.

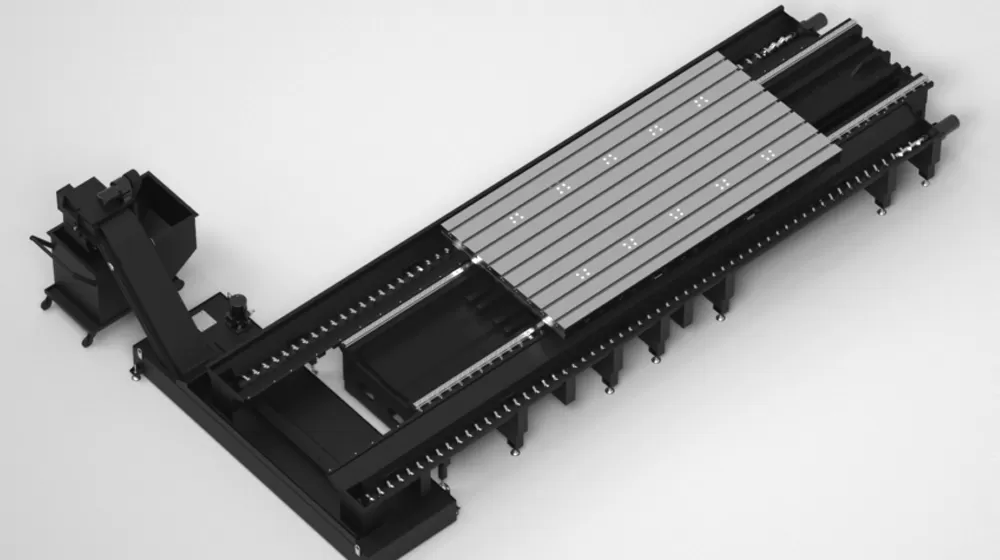

Chip Removal and Coolant Tank

Spiral Chip Conveyor: One set on each side of the worktable, with a 120mm screw diameter and large square steel cross-section, quickly expelling chips outside the machine.

Chain-type Chip Elevating Conveyor: Located at the machine's end, with a 45-degree incline, wider chain plate, and sawtooth scraper bars, quickly collecting chips into the small chip conveyor.

Small Chip Conveyor: Collects and transports chips.

Coolant Tank: Multi-layer filtration system to filter impurities and ensure smooth machining.

The machine is suitable for the multi-variety and small-to-medium batch processing of complex parts such as medium-sized box-type components, plates, discs, valves, and housings.

Item | Unit | G-V1018A | G-V1220A | G-V1225A | G-V1230A | G-V1018C | G-V1220C | G-V1225C | G-V1230C | ||

Travel | X-axis travel | mm | 1800 | 2150 | 2650 | 3200 | 1800 | 2150 | 2650 | 3200 | |

Y-axis travel | mm | 1100(+100 tool change) | 1500 (+25 tool change) | 1100(+100 tool change) | 1500 (+25 tool change) | ||||||

Z-axis travel | mm | 800 | 800 | ||||||||

Distance from spindle end to table | mm | 100~900 | 70~870 | ||||||||

Effective gantry width | mm | 1160 | 1560 | 1160 | 1560 | ||||||

Table | Table size (L×W) | mm | 1800×1000 | 2000×1250 | 2500×1250 | 3000×1250 | 1800×1000 | 2000×1250 | 2500×1250 | 3000×1250 | |

Max. load | kg | 3000 | 4000 | 5000 | 6000 | 3000 | 4000 | 5000 | 6000 | ||

T-slot (Width×Pitch×Qty) | mm | 22×140×7 | 22×160×7 | 22×140×7 | 22×160×7 | ||||||

Spindle | Drive type | / | Belt driven (Opt. gear driven) | Motorized spindle | |||||||

Max. spindle speed | r/min | 6000 | 15000 (Opt. 18000) | ||||||||

Spindle power (Rated/Peak) | kW | 15/18.5 | 15/22 | ||||||||

Torque output (Rated/Peak) | N.m | 191/315 (Opt. gear 573/945) | 45.7/73.6 | ||||||||

Spindle taper | / | BT50 | BBT40 (Opt. HSK-A63) | ||||||||

ATC (Opt.) | Number of tools | T | 24 | 24 | |||||||

Max. tool dia. (Full/Adjacent) | mm | Φ110/Φ200 | Φ80/Φ150 | ||||||||

Max. tool length | mm | 350 | 250 | ||||||||

Max. tool weight | kg | 18 | 8 | ||||||||

Speed | Feed rate range (Cutting) | m/min | 10 | 10 | |||||||

Rapid traverse speed (X/Y/Z-axis) | m/min | 16/16/12 | 16/16/12 | ||||||||

Accuracy | Positioning accuracy | mm | 0.015/0.012/0.012 | 0.02/0.012/0.012 | 0.015/0.012/0.012 | 0.02/0.012/0.012 | |||||

Repeatability | mm | 0.008/0.008/0.008 | 0.012/0.008/0.008 | 0.008/0.008/0.008 | 0.012/0.008/0.008 | ||||||

Others | Z-axis counterweight | / | Nitrogen balance | Nitrogen balance | |||||||

CNC system | / | FANUC 0i-MF PLUS (Opt. Mitsubishi M80, Siemens 828D) | FANUC 0i-MF PLUS (Opt. Mitsubishi M80, Siemens 828D) | ||||||||

Air supply | Flow | L/min | 280 (ANR) | 280 (ANR) | |||||||

Pressure | MPa | 0.5~0.8 | 0.5~0.8 | ||||||||

Total electrical capacity | kVA | 40 | 40 | ||||||||

Coolant tank capacity | L | 400 | 400 | ||||||||

Machine size | Length | mm | 4600 | 5100 | 6300 | 7800 | 4600 | 5100 | 6300 | 7800 | |

Width | mm | 4600 | 4900 | 4600 | 4900 | ||||||

Height | mm | 4500 | 4550 | 4500 | 4550 | ||||||

Machine Enclosure | - | Full perimeter sheet metal | Full perimeter sheet metal | ||||||||

Note: G-V1018B, G-V1220B, G-V1225B, G-V1230B are equipped with 6000rpm gear drive spindle.

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

FANUC

Siemens

Mitsubishi

Apr 11 2025

Apr 01 2025