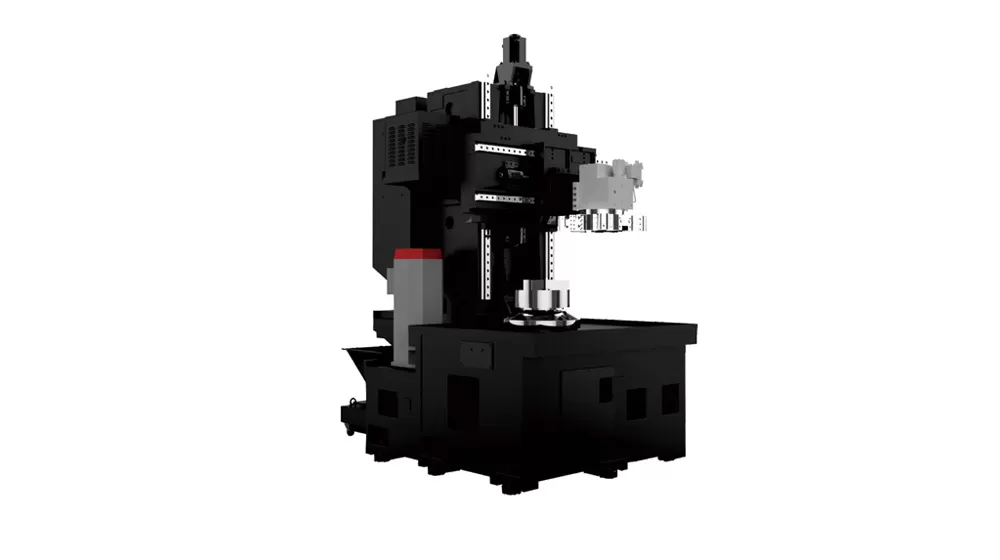

Main Structure

The crossbeam has high resistance to bending and torsion, ensuring stable cutting.

The column is a strong, vibration-resistant cast box structure.

The X/Z axes use high-load roller guides and pre-stretched ball screws to minimize thermal effects.

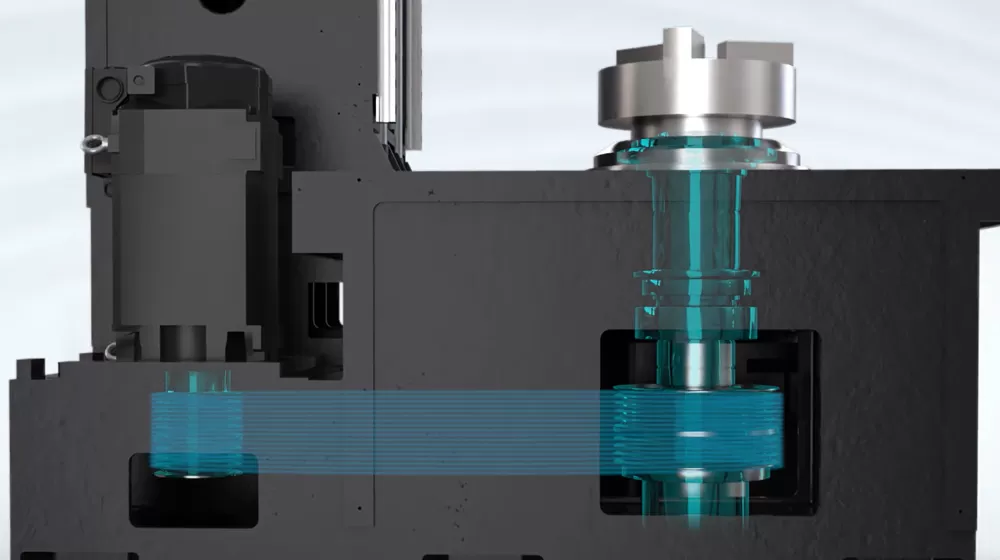

Spindle and Table

High-precision spindle units from top brands ensure accuracy and load capacity.

Driven by a Siemens servo motor, with speed reduction via a V-belt.

The table base includes a spindle encoder for constant surface speed cutting.

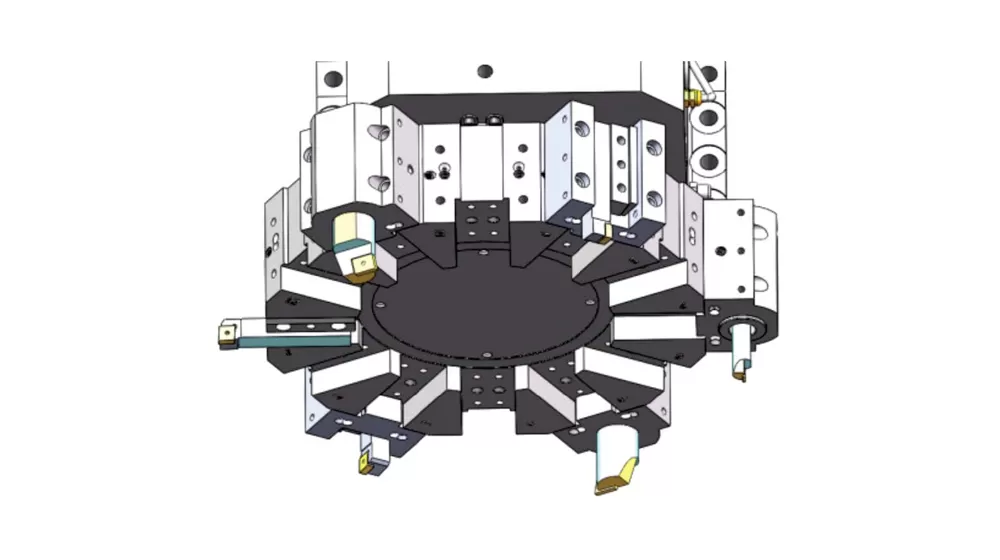

Standard Turret

8-position horizontal hydraulic turret for fast tool changes and high reliability.

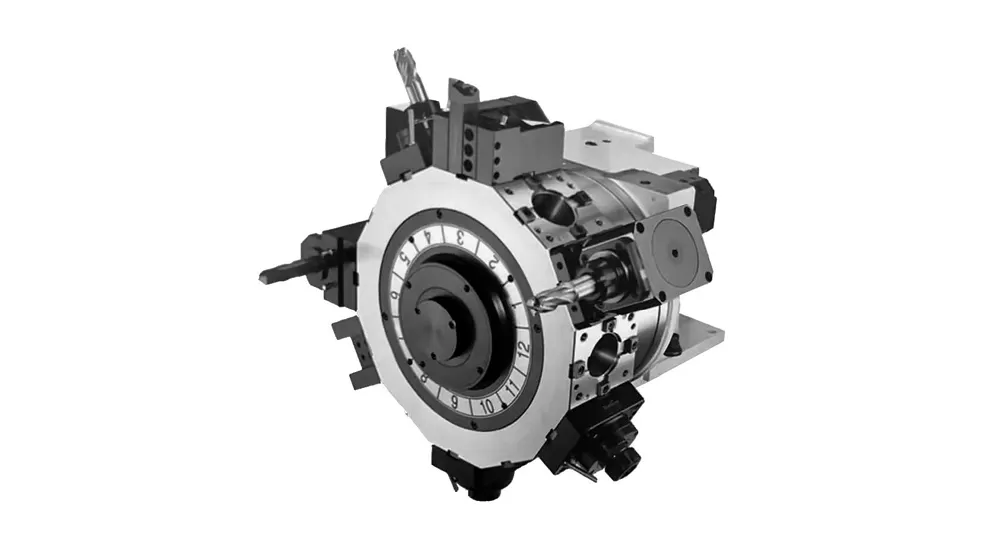

Optional Turret

Optional power milling turret, driven by a servo motor, designed to reduce noise.

Optional vertical turret, suitable for inner hole machining with minimal tool interference.

It is widely used in the manufacturing of automobile parts, such as hubs, brake discs, wheels, brake hubs, reducers, and more. It is particularly suitable for processing complex components like discs, shells, and short shaft parts used in bearings, energy, and other industries. The machine tools offer high precision, efficiency, and quality.

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

Item | Unit | D-VL500 | D-VL500M | |

Machining Range | Max Swing Diameter | mm | 650 | |

Max Turning Diameter over Carriage | mm | 500 | ||

Max Workpiece Height | mm | 500 | ||

Max Workpiece Weight | Kg | 500 | ||

Spindle | Chuck Diameter | inch | 12″(Hydraulic Chuck) | |

Spindle Speed Range | r/min | 50~2500 | ||

Max Spindle Torque | Nm | 900 | ||

Spindle Nose Type | / | A2-8 | ||

Spindle Centering Bearing Diameter | mm | 130 | ||

Main Motor Power (S1/S2) | KW | 12/22.8 | 12/23 | |

Tool Post | Turret Type | / | Horizontal (Vertical optional) | Horizontal |

Number of Positions | / | 8(6) | 12 | |

Drive Type | / | Hydraulic | Servo | |

Outer Diameter of Cutting Tool Holder | mm | 32×32 | ||

Inner Hole Tool Holder Diameter | mm | φ50 | ||

Feed | X/Z Axis Feed Guideway Type | / | Linear Guide | |

X/Z Axis Feed Rate | mm/min | 0.1~1000 | ||

X/Z Axis Rapid Traverse Speed | m/min | 20/16 | ||

X-Axis Horizontal Travel | mm | —20~315 | ||

Z-Axis Vertical Travel | mm | 520 | ||

X/Z Axis Feed Motor Torque | Nm | 12/22 | ||

Machining Capability | Power Head Motor Power | KW/Nm | / | 5.5/48 |

Max Drilling Capacity | mm | / | Φ20×0.2 | |

Max Tapping Capacity | mm | / | M16×2/M27×1.5 | |

Max Grooving Capacity | mm | / | Φ25×15×40 | |

Accuracy | Positioning Accuracy (X-axis) | mm | 0.01 | |

Positioning Accuracy (Z-axis) | mm | 0.01 | ||

Positioning Accuracy (C-axis) | " | / | 55 | |

Repeatability (X-axis) | mm | 0.006 | ||

Repeatability (Z-axis) | mm | 0.006 | ||

Repeatability (C-axis) | " | / | 25 | |

Other | CNC System | / | Siemens | |

Total Power Supply Capacity | kVA | 45 | 50 | |

Coolant Tank Capacity | L | 300 | ||

Footprint (Length×Width) | mm | 1750×3050 | ||

Machine Height | mm | 2600 | ||

Machine Weight (Approx.) | t | 6.5 | 7 | |

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Siemens

FANUC

Apr 11 2025

Apr 01 2025