Machine Structure

The machine features a bed-type, thermally symmetric structure, with major components made from high-strength cast iron to ensure stability and rigidity.

The bridge is vertically adjustable to accommodate parts of different heights, ensuring optimal rigidity for each machining task.

The movement uses a staged positioning system to maintain accuracy, with a floor-mounted tool magazine for improved efficiency.

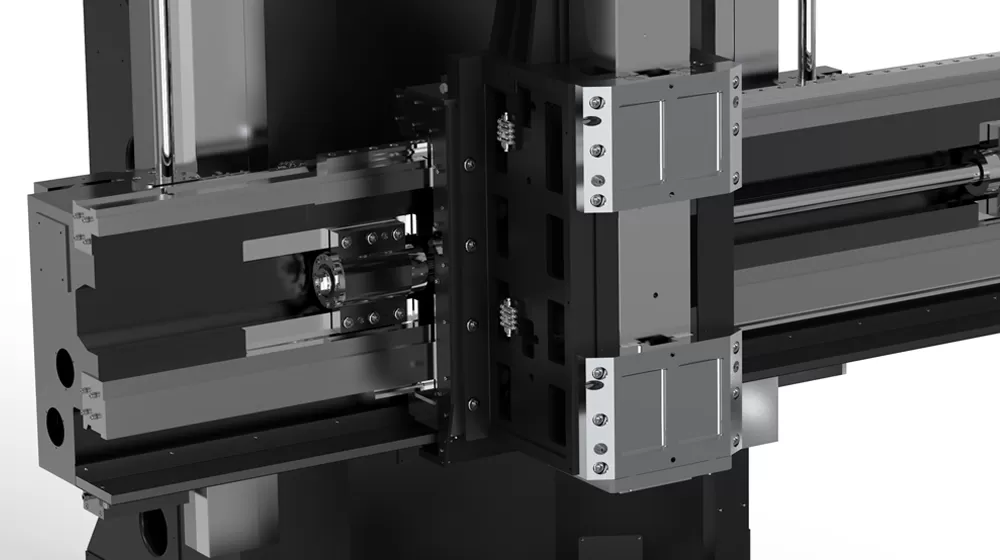

X-Axis Bridge

The large cross-section design enhances resistance to bending and torsion, ensuring stable cutting performance.

The combined roller-slide guide system provides low friction and excellent vibration damping, maintaining long-term precision and stability.

Z-Axis Ram

The large-section square steel ram is made from high-quality alloy forged steel, ensuring high rigidity and precision for heavy cutting.

The four-sided wraparound alloy steel guide with plastic coating offers excellent vibration absorption, ideal for powerful cutting applications.

Equipped with an internal BT-style turret spindle for automatic tool pull and release.

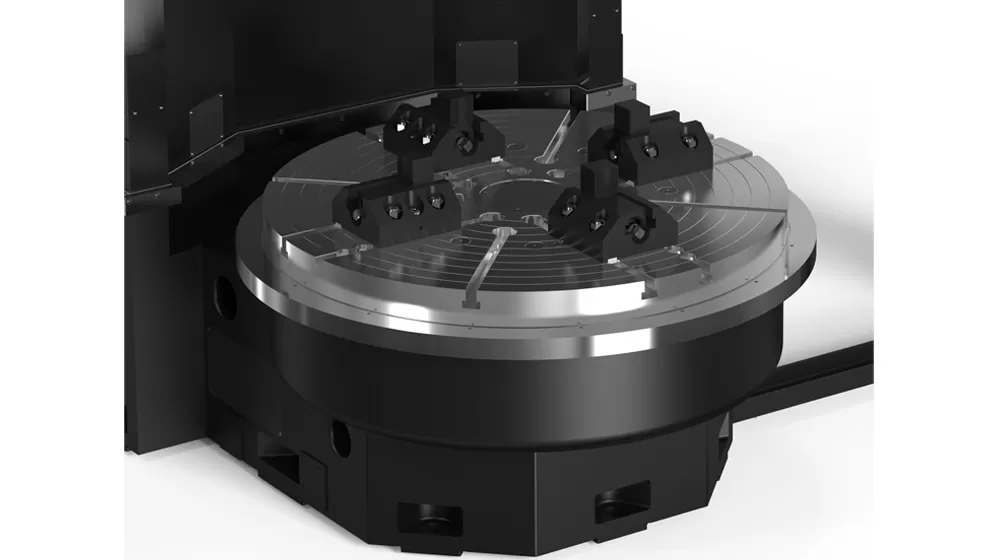

Table & Spindle

The axial direction uses high-precision thrust ball bearings with preload to ensure accuracy and extend the lifespan of the worktable.

The radial direction uses high-precision double-row cylindrical roller bearings for better precision.

The table's drive gear and bearings are lubricated by a cooling system, reducing temperature rise and minimizing thermal deformation.

The main motor is a high-torque unit, equipped with a gear reducer to provide wide spindle speed range and support heavy-duty cutting.

An encoder is installed on the worktable base to enable constant surface speed during cutting.

It is widely used in the manufacturing of automobile parts, such as hubs, brake discs, wheels, brake hubs, reducers, and more. It is particularly suitable for processing complex components like discs, shells, and short shaft parts used in bearings, energy, and other industries. The machine tools offer high precision, efficiency, and quality.

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

Item | Unit | D-VL1250C | D-VL1250CM | |

Processing Range | Max Turning Diameter | mm | 1250 | |

Max Workpiece Height | mm | 1000 | ||

Max Workpiece Weight | kg | 5000 | ||

Spindle | Table Diameter | mm | 1100 | |

Spindle Speed Range | r/min | 3.15~400 | ||

Milling Feed and Indexing Range | r/min | / | 0.04~2 | |

Max Table Torque | kN·m | 8 | 20 | |

Main Motor Power | KW | S1=31,S2=37 | S1=31,S2=37(two sets) | |

Turret | Tool Turret Type | / | Turning Center | Turning-Milling Center |

Saddle Cross Section | mm | 220×220 | 280×280 | |

Tool Positions | / | 8 or 12 | 8 or 12 | |

Outer Diameter Turning Tool Holder Size | mm | 32×32 | 40×40 | |

Turning Center Output Interface | / | BT50 | BT50 | |

Feed | X-axis Feed Guideway Type | / | Box Guideway / Linear Guideway | |

Z-axis Feed Guideway Type | / | Box Guideway | ||

X, Z-axis Cutting Feed Range | mm/min | 1000 | ||

X, Z-axis Tool Turret Rapid | m/min | 12/10 | ||

X-axis Horizontal Travel | mm | —50~850 | ||

Z-axis Vertical Travel | mm | 1000 | ||

X, Z-axis Feed Motor Torque | Nm | 37/25 | ||

Crossbeam | Crossbeam Vertical Travel | mm | 600 | |

Crossbeam Indexing Pitch | mm | 200 | ||

Crossbeam Indexing Steps | / | 4 | ||

Milling Spindle | Milling Spindle Motor Power | KW | / | S1=31,S2=37 |

Milling Spindle Speed | r/min | / | 10~2000 | |

Milling Spindle Taper Hole | / | / | BT50 | |

Max Milling Spindle Torque | N·m | / | 1200 | |

Accuracy | Positioning Accuracy (X/Z) | mm | 0.02 | |

Repeatability (X/Z) | mm | 0.01 | ||

Others | CNC System | / | Siemens | |

Total Machine Power | kVA | 75 | 85 | |

Coolant Tank Capacity | L | 600 | ||

Machine Footprint (L×W) | mm | 5550×3750 | ||

Machine Height | mm | 4650 | 6450 | |

Machine Weight (approx.) | t | 21 | 25 | |

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Siemens

FANUC

Apr 11 2025

Apr 01 2025