Single-Head High-Speed Precision Engraving Center

Syntec High-Speed, High-Precision CNC System

Powered by the advanced Syntec CNC system, ensuring high-speed and high-precision

Fixed-Beam Gantry Design

Cast iron bed and beam provide excellent rigidity and stability, ensuring consistent machining accuracy.

Compact Design

The compact footprint reduces the required floor space, ideal for space-constrained workshops.

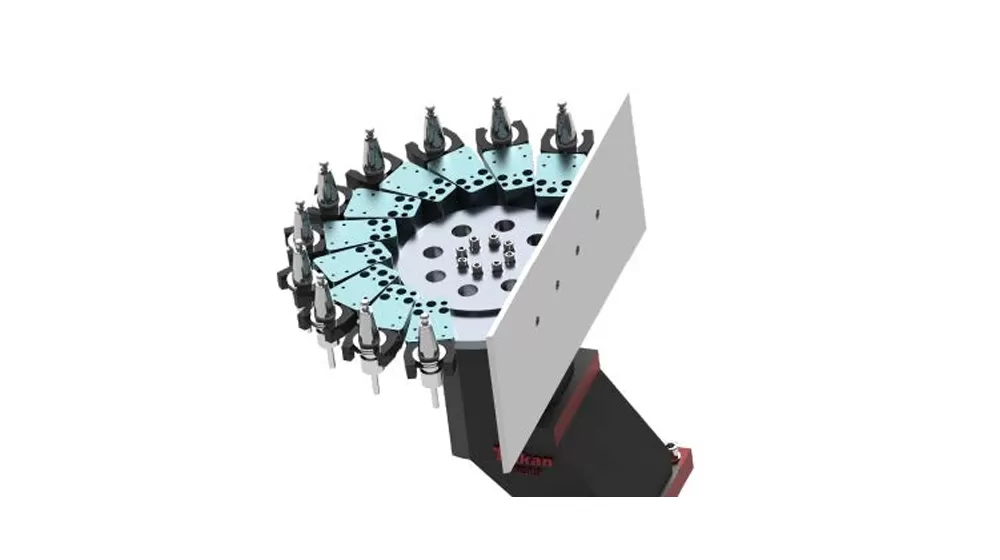

15-Tool Servo Tool Magazine

Equipped with a 15-tool servo-driven tool magazine to support efficient multi-process machining.

The C-400E is designed for precision machining of small aluminum alloy components and copper parts.

Workpiece Example 1

Workpiece Example 2

Workpiece Example 3

Workpiece Example 4

Name | Item | Parameters |

worktable | Worktable size (mm) | 400 * 400 |

Distance from worktable to spindle nose (mm) | 160∼ 310 | |

Max. load (Kg) | 100 | |

Travel | X travel (mm) | 400 |

Y travel (mm) | 400 | |

Z travel (mm) | 150 | |

Spindle | Spindle power (Kw) | 4.0 |

Max. spindle speed (rpm) | 40000 | |

Spindle diameter (mm) | φ80 | |

Spindle tool change method | Pneumatic | |

Tool holder specifications | IS020 | |

Feed speed | Max. feed speed (m/min) | 15 |

Max. cutting feed speed (m/min) | 8 | |

Accuracy | Positioning accuracy: X/Y/Z (mm) | 0.005 |

Repeated positioning accuracy: X/Y/Z (mm) | 0.004 | |

Tool magazine | Tool magazine capacity (T) | 15T |

Tool magazine form | Semi-umbrella servo tool magazine | |

Power Source | Air machine pressure (Mpa) | ≥0.6 |

Total power consumption (Kw) | 8 | |

other | External dimensions (front and back * left and right * up and down mm) | 1550*1450*2082 |

Weight (approximate weight: Kg) | 1900 | |

Whether to configure network transmission and monitoring functions | Have | |

Whether to configure tool setting instrument | Have |

The information on this page is for reference only. Specifications and details may change due to product upgrades or improvements. For more information, please contact us.

Mitsubishi

FANUC

Siemens

SYNTEC

Apr 11 2025

Apr 01 2025