-

Products

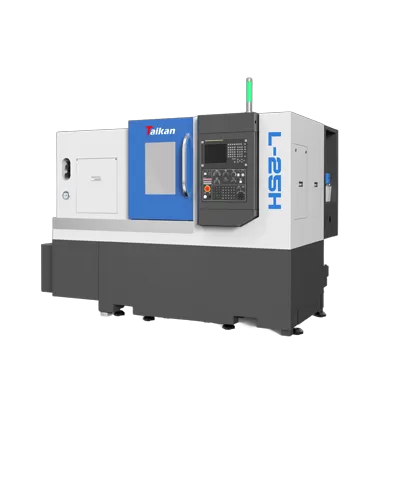

Vertical Machining Center Drilling and Milling Machining Center Profile Machining Center Horizontal Machining Center 5-Axis Machining Center Gantry Machining Center CNC Multi-Head High-Speed Machining Center CNC Lathe CNC Slitting Automatic LatheS series Standard Edition with 3-Axis Linear Guide Rails H Series Advanced Edition with 3-Axis Linear Guide Rails M Series Excellent Rigidity T-V Series Light Cutting W Series Hub Machining L Series Two Rails and One Hard Rail T Series 3-Axis Hard Rail DT Series High Precision Vertical Machining CenterB Series Drilling & Milling Machining Center S Series Drilling & Milling Machining Center SE Series Drilling & Milling Machining CenterT Series Moving Column Type & BT30 (Tilt-Disc Tool Magazine) V Series Moving Column Type & BT40 (Tilt-Disc Tool Magazine)T-H11 Horizontal Machining Center DH-63 Horizontal Machining Center DH-100S Horizontal Machining CenterG-V Series 3-Axis Linear Guides G-VU Series 5-Axis Gantry Machining Center G-BU Series Bridge 5-Axis Gantry Machining CenterSingle-Head High-Speed Engraving Machining Center Multi-Channel High-Speed Machining Center Multi-Head High-Speed Engraving Machining Center Multi-Head Vertical Machining Center

Vertical Machining Center Drilling and Milling Machining Center Profile Machining Center Horizontal Machining Center 5-Axis Machining Center Gantry Machining Center CNC Multi-Head High-Speed Machining Center CNC Lathe CNC Slitting Automatic LatheS series Standard Edition with 3-Axis Linear Guide Rails H Series Advanced Edition with 3-Axis Linear Guide Rails M Series Excellent Rigidity T-V Series Light Cutting W Series Hub Machining L Series Two Rails and One Hard Rail T Series 3-Axis Hard Rail DT Series High Precision Vertical Machining CenterB Series Drilling & Milling Machining Center S Series Drilling & Milling Machining Center SE Series Drilling & Milling Machining CenterT Series Moving Column Type & BT30 (Tilt-Disc Tool Magazine) V Series Moving Column Type & BT40 (Tilt-Disc Tool Magazine)T-H11 Horizontal Machining Center DH-63 Horizontal Machining Center DH-100S Horizontal Machining CenterG-V Series 3-Axis Linear Guides G-VU Series 5-Axis Gantry Machining Center G-BU Series Bridge 5-Axis Gantry Machining CenterSingle-Head High-Speed Engraving Machining Center Multi-Channel High-Speed Machining Center Multi-Head High-Speed Engraving Machining Center Multi-Head Vertical Machining Center - Applications

- Service

- Investor

- News & Media

- About Us

- Dealer Portal

- Contact Us

EN

EN